How to make a wooden staircase to the second floor with your own hands. How to make a wooden staircase to the second floor with your own hands - drawings and instructions

Stairs- this is one of the main elements of the interior design of the room, therefore, when designing it, attention should be paid not only to reliability and functionality, but also to the appearance. Before taking on making a wooden staircase with your own hands, it is necessary to take into account a large number of factors on which not only its design, but also its dimensions will depend.

These factors include:

- affordable room area,

- height,

- maximum load for which the ladder is designed,

- ease of use for people living in the house.

To date, there are a huge number of options for the execution of interfloor stairs, so choosing the right design is a rather difficult task.

Choosing which staircase to build

Stairs marching and spiral. The design of the mid-flight stairs is quite simple and is the best choice, if you plan to make it yourself, however, in order to provide an acceptable slope and height of the steps, a considerable area is required. This ladder is very easy to use and can withstand heavy loads. It can easily lift furniture and other large items to the second floor, in addition, it is safer, so it will be the best choice if children or the elderly live in the house.

The spiral staircase has a more complex device. It is used in conditions of limited space, when, due to lack of space, it is not possible to provide a safe slope for an ordinary staircase. The main disadvantages include a not very convenient design, which makes it difficult to lift and does not allow you to carry large items. At the same time, a skillfully executed spiral staircase has sufficient strength and can be the main element of the interior.

Safety above all!

Before proceeding to making stairs with your own hands need to take care of its safety. Firstly, it must be strong and easily withstand a load several times greater than the weight of a person of average build. Secondly, the ladder should be comfortable and ergonomic. In this case, it is necessary to pay great attention to such factors as the height of the steps, the slope of the stairs, as well as the location and shape of the railing. The steps should have a non-slip coating, and the gaps between the balusters should be chosen so that the child cannot squeeze through them and fall.

Design features of stairs

Depending on the method of fastening the steps, marching stairs can be on bowstrings, stringers or bolts.

- Ladders on bowstrings have two side beams to which steps are attached. Such squirrels (strings) can be made of metal or wood. They can be attached to the wall or special supports, providing high strength of the entire structure.

- The steps of the stairs on the stringers are attached to the beams, which are located below and repeat the geometry of the entire structure. Such beams (kosoura) can be straight or curved. Straight stringers, as a rule, have a jagged shape, while the steps are superimposed on the teeth.

- Stairs with a bolt connection of steps are highly durable, so this design does not require additional supports and can be held at two points. The steps are attached to each other with metal rods - bolts, which completely eliminates the creaking caused by the friction of two wooden surfaces.

How to make a staircase with your own hands. Choosing materials

For the manufacture of stairs, softwood is most often used, since it is affordable and easy to process. An oak staircase will be more durable, but the cost of such a design will increase several times, moreover, the processing of this type of wood is a rather laborious task and requires certain skills.

The main steps in the manufacture of stairs

Let's consider the basic principles of making stairs using an example wooden structure on stringers. Before starting the design, it is necessary to understand that any, even minor errors and inaccuracies in the calculations can lead to serious problems that will arise during installation, so each step should be taken very carefully. Our future staircase will consist of three main elements: steps, handrails and stringers. On the initial stage design needs to be done necessary calculations designs.

Calculation of the width and height of steps

To calculate the size of steps, the formula 2A + B = 64cm is usually used, where A is the width and B is the height. Typical step heights range from 140 to 170mm. We measure the height of the future stairs and divide by the estimated value of the height of the steps.

Suppose it is 240cm, and the desired height of the steps is 17cm. We divide the resulting value by the height of the steps 240/16=15 and round the result to the nearest integer, therefore, our future staircase will consist of 15 steps. Now we determine the exact height of the steps, for this we divide the height of the entire staircase by the number of steps: 240/15 \u003d 16cm. We find the width by the formula, using the height value, we get 24cm. You can also use a table.

The protrusion (part of the step hanging over the riser) should be no more than 3-4 cm. The greater the height of the riser, the narrower the step itself, but its width should not be less than the height. The most optimal step width should correspond to the forty-second shoe size (29-30cm.)

When calculating the stairs, it is also necessary to take into account the distance between the steps and the objects located above them (ceiling, beams, balconies, etc.). It should be at least 1.9-2 meters.

The horizontal size of the stairs is determined as follows: the width of the steps is multiplied by their number, while it should be taken into account that the floor surface serves as the first step, so in our case the calculation will look like this: 13x24=312cm.

If the height of the stairs is large enough, you can make a platform. Such platforms are recommended to be done in 7-8 steps. In the case when it is necessary to design a staircase with a certain number of steps, you can reduce their height in order to make a platform.

Manufacturing of stringers

As a material for the manufacture of stringers, you can use a 40mm wide pine board. Make a pattern that exactly repeats the dimensions of the profile of the steps and mark the prepared boards. Then cut the teeth with a hacksaw or electric jigsaw. In those places where the riser joins the step, it is necessary to cut off the corner. Having made one kosour, you can use it as a template for the rest. Since the strength, safety and durability of the stairs depend on the stringers, you should not save on their quantity, as well as on the quality of the material from which they are made. Boards should be free of knots and any signs of insect activity. Consider a way to attach stringers. To achieve the required strength, as a rule, 3-4 stringers are enough.

Installation of steps and railings making wooden stairs with your own hands

Steps can be attached directly to the stringers, or with the help of additional wooden elements - filly. Measure and cut out the required number of steps and risers from wood, and do not forget to take into account the ledge. Steps are fastened with nails or self-tapping screws.

The design using triangular fillies is more reliable. The fillies are fastened using dowels, for which grooves are previously made. The most durable construction is obtained using complex-shaped fillies, while a special cutout is made on the stringers. The connection of the elements of the stairs is carried out with the help of glue and self-tapping screws.

After the steps are ready, you can screw the railing balusters to them. In order to protect the tree from the influence of destructive factors (dampness, mold of harmful insects), it is necessary to apply a paint and varnish coating on it.

Do wooden stairs Do-it-yourself, in principle, is not so difficult. All you need for this is quality wood, essential tool and a little patience. Before starting work, carefully consider all the nuances of the future design and check the preliminary calculations several times.

Even if you have at least once held a saw and a hammer in your hands, you are quite capable of making a simple wooden staircase to the second floor. The main thing is to strictly follow the instructions and not make a mistake in size. If you have experience in carpentry, you can cope with more complex structures.

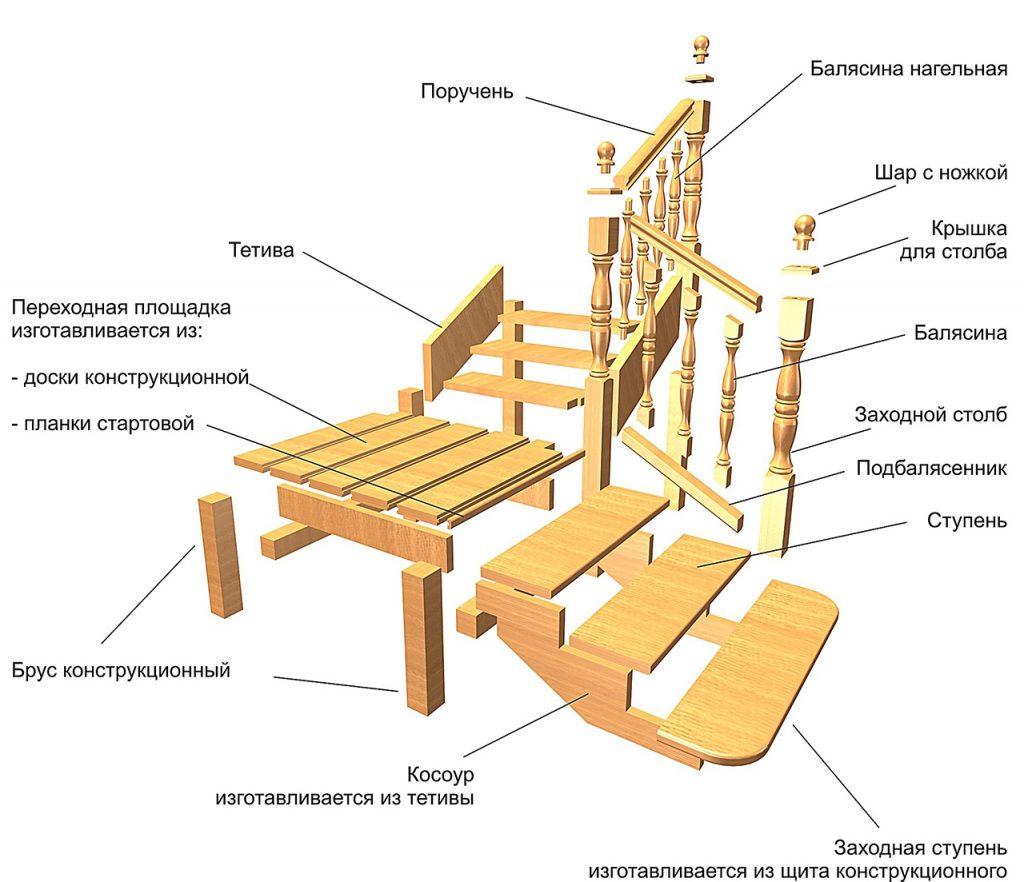

Basic terminology

There are many terms in carpentry that are rarely used in everyday life. Therefore, before proceeding with the manufacture of stairs, consider the name of each of the elements and understand their purpose.

Its main components include:

- bowstring: an inclined beam that runs along the entire flight of stairs, steps are attached to it from the inside

- stringer: another type of carrier beam, unlike a bowstring, steps are attached to it from above

The difference between a kosour and a bowstring

- filly: when attaching steps to a bowstring beam, the use of grooves or sockets thins the beams; a more reliable method is mounting on special elements of complex shape, called fillies; they are attached to wooden bars - dowels; filly can be replaced with steel corners screwed to inside strings

- flight of stairs: an element assembled from several steps (there can be from 3 to 18), located between the platforms, located at an angle

- supporting pillars: used to strengthen the structure, wood can be replaced by metal

- steps for a wooden staircase to the second floor: they are divided into frieze (upper and lower), their design differs significantly from the rest, called ordinary

- tread: part of the step, located horizontally, it is on it that we step when walking

- riser: detail fixed vertically tread; open stairs risers may or may not have

- landing: a platform for connecting marches; in combined versions it may be absent, replaced by winder (unequal in width) steps, that is, one end of it is made wider than the other

- railing: vertical railings

- balusters: railing supports

- handrails: parts of the railing connecting the balusters from above

- balustrades: railing from curly posts

In addition to fastenings on stringers and bowstrings, to save space, structures with bolt flooring are used. Steps with the help of bolts (fasteners connecting bearing wall and handrail) are attached directly to the railing. To ensure strength, the frame is attached to the load-bearing wall.

Despite the external lightness, the structure is able to withstand the weight of several hundred kilograms. But it requires high precision during installation and competent calculation of nodes.

Types of stairs. Project selection

There are a lot of models of wooden stairs. There are three main types:

- marching: consisting of several spans (see photo); in turn, they are divided into straight and rotary (with intermediate platforms) models

- screw: the steps in them are attached in a spiral to a vertical support or a curved bowstring; such structures occupy a minimum of space, they can be located even in a small area of 1.5 m; plus, thanks to their attractive appearance, they fit perfectly into the interior; but their design is more complex, assembly requires some experience; prices for finished wooden stairs to the second floor of a similar form are quite loyal, so they can be purchased ready-made

- combined: a combination of straight, circular, rotary elements; designers are able to turn an ordinary design into a real work of art

Types of stair marching structures

The shape of the stairs can be ordinary straight, rotary, have the form of the letters "G", "P" or "S". Combined structures are rounded, pyramidal, semi-, quarter-turn, in the form of a trapezoid or consist of several sections.

Read also:

Read also: Basic requirements for flights of stairs

At wrong choice the dimensions of the tread, risers, the angle of inclination of the march and the width of the structure, it will be very inconvenient to walk up the stairs and carry bulky objects along it. Therefore, when creating it, one should adhere to generally accepted standards.

According to GOST, the minimum width of the opening should be from 0.6 m. But it is advisable to make even a narrow staircase to the attic floor larger, 0.8-1.0 m wide. This size will be quite enough for one person to pass through, as well as to carry enough overall things.

Wide structures with a step length of 1250-1500 mm look more impressive. Two people can climb on them, as well as carry even bulky furniture.

The most important parameter is also the size of the steps. It will be uncomfortable to walk on steps that are too high, so do not make them higher than 16-19 cm. The width of the tread should be equal to the length of an adult's foot and average 30-32 cm. Slightly smaller steps can only be made for attic or basement spaces.

To maintain the balance of a person when walking, the steps are always made the same. Otherwise, each of the steps will have to grope with your foot.

In order for a person to be able to start climbing stairs with one foot, the number of steps in each of the marches is made odd. The number of steps in one of its march can reach up to 18. More of them should not be done, otherwise the ascent may be difficult.

It is better to provide an intermediate platform for a short respite. The minimum number of steps, according to the rules, in one march is 3.

Read also:

Read also: Production of a single-flight staircase

Let's start the description of the process of manufacturing a wooden staircase to the second floor with our own hands from the simplest marching structure. For most parts, a board 50-60 mm thick is sufficient, from which the required blanks are cut. Stringers or bowstrings, which will bear the main load, are made of lumber with a thickness of 60-80 mm.

So that the tree does not lead over time, it is well dried. It is desirable that the humidity is up to 6%. To avoid injury, lumber should not have a large number of knots and cracks. The most wear-resistant wood species that can last for decades include oak, beech, and pine. Lumber from larch, ash, alder is considered strong enough. For the manufacture of balusters and railings, less wear-resistant linden or aspen can be used.

The wood used for the manufacture of stairs must be treated with a special impregnation, and then painted or varnished. This must be done once every few years during the entire operation.

Read also:

Read also: Making a drawing

The wooden staircase to the second floor (see photo) has a lot of details, and in case of an error in the calculations, it will be simply dangerous to use it. Therefore, even experienced carpenters will never start work without preliminary calculations. You can use ready-made drawings only if the height of your ceilings and the size of the area allotted for the stairs completely match the indicated data. When designing, it is also necessary to take into account the configuration of the room, the location of doors and windows.

The simplest drawing of a marching structure is easier to make yourself. After all, it looks like a regular triangle. The most comfortable building is considered to be with tilt angle 40-45° (triangle aspect ratio should be 1:1.5). However, this option is only suitable for very large rooms. After all, it will occupy a significant area.

When designing, it must be taken into account that the distance from the last step to the ceiling is 1.85-2 m.

It is not worth making the design even flatter, otherwise it will take up more space. Going down a steep descent with an angle of more than 50-60 ° C will simply be dangerous. Therefore, if the ceilings are too high, in order to save space, it is better to stop on a turning staircase, for example, “G” or “P”-shaped with small, 10-12 steps long, marches. Read also: How to make gabions from a grid with your own hands: we turn country cottage area in a cozy corner, decorated with designer taste | 120+ Photos & Videos

Basic calculations

There are special programs on the network that allow you to do all the necessary calculations automatically. However, it is better to play it safe and do it manually.

For example, the height of our ceiling is 250 cm. To this parameter it is necessary to add the thickness of the floor plus the thickness of the ceiling between 1-2 floors. We get 285 cm. We draw a triangle on a piece of paper, one of the sides of which will be 285 cm (on a scale on an expanded notebook sheet 28.5 cm).

We draw an inclined line from it at an angle of 45 ° (as we already know, this is the standard angle of inclination of the stairs). We measure the side of the triangle. It will be equal to 4.03 m.

We check our data based on the Pythagorean theorem. Determine the length of the march:

c = sin 45°/b,

According to the table of sines, sin 45 ° is 0.7071; b in our case will be equal to the height of the ceiling. Let's do the calculations:

285 / 0.7071 \u003d 403.05 cm or 4.03 m.

But in a small room, a 4.03 m long staircase will look too cumbersome. It is better to make it two-flight with a rotation angle of 180 °. The calculations will be similar. Do not forget to take into account the height of the intermediate platform.

To determine the length of the kosour (string), that is, the longest side of our triangle, we use the Pythagorean formula:

h 2 + l 2 \u003d k 2,

where for l the length of the march is taken (403.05 cm), and h equals the height of the stairs (250 cm). When a fractional result is obtained, the figure is rounded up to the full number. We get the length of the kosour, equal to 474.29 cm.

The width of the kosour (string) is equal to twice the height of the riser (multiply its height by 2).

Number of steps will be equal to 285/17 = 16.77 pcs. The number 17 is the height of the risers we have chosen (their height can be 16-19 cm). Since experts recommend choosing an odd number of steps, no recalculations are required in our case.

If we get an even number, we can change the calculations and make the bottom and top steps smaller in size.

Read also:

Read also: Marking stringers

Assembling a ladder with stringers is much easier than with a bowstring. After all, you do not have to prepare grooves for steps. But there are subtleties in working with a kosour - after all, for each of the steps in an inclined beam, you will have to make cuts in the form of a comb of equal size.

To do this, it is easier to use a template (see photo). The letter "a" in the figure means the height of the step, the letter "c" - the length of the tread. The already finished first stringer can be used as a template for cutting the second stringer. Be sure to attach both stringers to each other - they must match exactly.

At the bottom of the stringer with an indent of 7 cm from the edge, a slot is made to install it on a support.

At the top of the stairs, it will also rest on a beam. For this, a groove is also made in it. The width of the cut should be equal to the width of the stringer itself.

Fastening risers to three stringers

In any building higher than a floor, a staircase is installed. Such a design requires a detailed calculation of all its components, the ability to work with metalwork and carpentry tools, and some design skills. After studying this instruction, you will learn how to design and manufacture a wooden staircase with your own hands.

A wooden staircase for a private house most often consists of one or more flights (spans), which are located between floors or intermediate platforms.

Design flight of stairs is a combination of various components with different functional purposes:

- Kosour. It is a load-bearing beam made of wood with a sawn comb. Risers with steps are fixed to it, so the part must be durable.

- Bowstring. In some cases, it becomes an alternative to the stringer, performing load-bearing functions (especially if one side of the structure is adjacent to the wall). Before installation, the bowstring must be marked in detail so that the steps are located at a horizontal level.

- Step. The main element of any staircase, which is attached to one of the load-bearing beams. In addition to the usual ones, there are running and radius steps. The running elements have a non-standard shape and are mounted at the starting point of the march. Radius steps are characterized by a curvilinear leading edge, they can be semicircular, wavy or with rounded corners.

- Riser. The detail is optional, but it provides the ladder with high strength by keeping the step centered. A spacer is used to fix the riser. A radius type is installed under the semicircular steps, and the curved version is mounted under the corresponding steps or under the platform between flights of stairs.

- Poles for support. They are placed at the starting and ending points of the stairs, as well as along the edges of the inter-march platforms. The elements increase the strength of the fence and serve as a support for the handrails.

- Balusters. These are retaining posts for the handrails, from which the side rails are formed, can have a different configuration.

- Handrails. They are a required item. They rest on balusters and support posts. The main requirement for the element is a smooth surface.

- Remote bushing. Such a stand is required for any design with several flights (even when using stringers).

When choosing a staircase, the main factor is the size of the area required for its construction. In second place is the convenience and comfort of ascent and descent. Here you need to take into account the frequency of use, the presence of children and the elderly in the house.

Aesthetics is also an important criterion. The staircase should be combined with the interior of the room. In addition, it is necessary to take into account the material possibilities: the manufacture of wooden stairs with a complex configuration requires more time and financial costs than simpler in form and execution options.

marching

are the most popular. They got their name thanks to marches (flights) - a group of combined steps. A staircase can have one or more flights.

There are direct structures (one-march and two-march, with a platform for rest). They can be freestanding or placed near a wall. But straight models require a lot of space, so in order to save usable space, two-flight options are provided with an angle of 90 to 180 degrees.

The march has a curvilinear shape with an optimal angle of elevation, then turning steps are used, which are also available for structures with two and three marches without platforms.

The most popular types of wooden stairs for a country house are:

- Ordinary single-march. They have a simple design with a span in the center of the room or near the wall - the most durable with reliable support.

- Curvilinear single-march. Installed in large rooms to emphasize spaciousness. They are characterized by a smooth turn and extended with outside steps.

- Marching with lower turning steps. Sometimes this option is provided by the layout of the room, it can support the chosen architectural style.

- Simple 2 march system. A staircase with two flights and with an interfloor turntable can be mounted above the door and save space.

- 2 march L-shaped design. It is located in a rectangular opening along perpendicular walls and saves space.

- 2-way U-shaped staircase with an upper platform and turning steps. The design is mounted in luxurious mansions with a large hall.

- 3 march system with two platforms. This type of stairs saves space, but requires a significant ceiling height.

To select a specific configuration, you should correctly calculate and measure the free area for installation, draw up a drawing. Detailed guide how to do this will be below.

screw

Screw-type structures are used less often, as a rule, with a limited area or for aesthetic reasons of the owner of a private house. They are not as comfortable as marching ones, it is difficult to transport furniture along them. To install a ladder, you will need to perform complex calculations, since with a small error it may lose its functionality.

Spiral staircases sometimes perform a purely decorative function, especially with a fence made of artistic forging. The device of such options is possible in almost any room, because. they take up less space than swivel designs. There are the following types:

- with cantilever pinching steps on the inner column;

- with support of steps on the inner pillar and perimeter walls;

- with cantilever support of steps on the casing pipe;

- based on a fence and bent bowstrings.

Spiral staircases save space

Spiral staircases save space Types of structures

Before you make a wooden staircase, you should pick up best option structures for your space.

The following popular types of structures exist:

The simplest is a straight staircase, which provides straight-line movement along the march.

Making a wooden staircase with your own hands with a visual step-by-step instruction will be considered in more detail. The process includes two main stages: design and installation.

Calculations of the dimensions of the staircase

Before you start designing, you need to make accurate calculations, draw a diagram and put all the data on it. If there is no confidence in the correctness of the calculations, then it is better to entrust the work to professionals who will make a competent drawing, which will allow the installation to be carried out step by step without errors.

Total height of stairs

You can determine the height by measuring the distance from the floor of the first to the second floor, taking into account the thickness of the ceiling. For example, if on the 1st floor the ceiling height is 2700 mm, and the thickness of the interfloor ceilings is 300 mm. As a result, the total height will be 3000 mm.

If there is no finishing floor, then its dimensions must be laid approximately.

Number of steps

If you know the height of the stairs and the riser, you can determine the number of steps in the structure. To do this, you need to divide one indicator by the second. For example, with a total staircase height of 3000 mm and a riser height of 175 mm, the calculation would be: 3000: 175=171 mm.

After that, you need to round the value, the result will be 170 mm. The table shows an example of the calculation:

The dependence of the height of the steps on their number at a given floor height

The dependence of the height of the steps on their number at a given floor height Riser height

According to the recommendations of experts, the optimal riser height should be 150-180 mm, in fact, this is the size of a human step. This height can be 150–200 mm. Usually the average value according to the standard is 160-170 mm.

The optimal stair slope range is highlighted in green

The optimal stair slope range is highlighted in green Step width

In order to avoid injuries as a result of incorrectly selected step widths, you need to calculate it correctly. Based on many years of practice, the width of the part should be in the range of 220 - 400 mm.

To determine a more accurate value, you can use a certain formula. You need to take the average width of a human step (600 - 640 mm) and subtract from it the height of the riser multiplied by 2, i.e. 640 - 2x175 = 290 mm. This indicator will be optimal for moving.

March width

According to safety rules, for the convenient movement of people, the span should be at least 80 cm wide, but it is better to take at least 90 cm. For convenient transportation of furniture, this indicator for a private residential building should be 100 - 120 cm.

Ladder length in plan

To calculate this parameter, you need to multiply the number of steps and the width of the tread. In our example, it will turn out 29x17 \u003d 493 cm. That is, the staircase comes out quite long and when arranging one march, a room of at least 6 meters will be required. In a small log house or a village house, you will need to make 2 flights with a 90 or 180 degree turn.

A platform is mounted between the marches or turning steps are placed. If it is not possible to perform the calculation on your own, you can use the special program presented just below, which will clearly reflect the localization of stair parts.

Ceiling opening size

When building a staircase made of solid wood, you need to remember about the calculation of the ceiling opening so that you don’t have to bend down when lifting up. Such an indicator will depend on the slope, which affects the convenience when moving and is selected individually.

A slope of 23-36 degrees is considered optimal, but it is often impossible to maintain the required angle due to the small area of \u200b\u200bthe room (the steeper the slope, the less area it will occupy).

The size of the opening in the ceiling area will depend on the angle of the flight of stairs. So, a folding structure will require a small opening, and a larger slope will require a larger one (up to 2 m).

The size of the opening in the ceiling is determined based on the minimum allowable value for the passage of a person

The size of the opening in the ceiling is determined based on the minimum allowable value for the passage of a person Stringer length

To determine the length of the kosour, the Pythagorean formula is used: (length of the stairs in the plan) ² + (height of the stairs) ² \u003d (length of the kosour) ².

That is, with a length of 493 cm and a height of 300 cm, we get the following: L \u003d √ (4932 + 3002) \u003d 577 cm (the indicator is taken with a margin of 580 cm).

Online calculator for calculation

For your convenience, you can use the convenient and visual.

Material selection

After all the calculations are made, you need to purchase materials. This will require boards of different lengths and densities: for steps, the thickness is 3-4 cm; for risers - 2-2.5 cm; for a bowstring or stringer, the thickness is 5 cm, and the height is 150-250 mm. It is better to buy handrails and balusters ready-made, since their production will require lathe and a bar measuring 10x10, 15x15 cm. To fix the components, you will need self-tapping screws and nails, as well as metal corners for reinforcement.

Production of parts and installation of stairs

Installation technology includes the manufacture and installation of all elements of the ladder structure in accordance with the drawing.

Assembling a bowstring or stringers

On the prepared boards, you need to mark the length and saw off the excess. On the bar, using a square, mark the height of the substep and the width of the tread with a decrease of 2-4 cm.

Marking a one-piece stringer

Marking a one-piece stringer

Assembling a bowstring with stiffeners

Assembling a bowstring with stiffeners Notches for steps are cut with a jigsaw or saw. Next, the workpiece is attached to the installation site so that the lower edge rests on the floor, and the upper edge rests on the ceiling. The cuts under the steps should be horizontal, without "blockages". After that, it is recommended to grind the surface of the bar, perform milling, rounding the outer edges.

For optimal rigidity, sometimes 2, 3 or 4 stringers may be required, the number of which is selected depending on the width of the stairs. Sometimes it is easier to order a ready-made load-bearing frame, which will include all the elements with cutouts, indicated by numbers for joining in accordance with the diagram.

Installation of steps and risers

The risers are mounted in the prepared cuts of the stringer, leveled and sanded. Fastening is carried out using self-tapping screws, which can then be puttied or closed finishing material.

Options for attaching steps to the bowstring

Options for attaching steps to the bowstring After fixing the risers, pre-milled steps are installed, the length of which should exceed the distance between the pair of extreme stringers by 1-2 cm. The width of the elements should be 2-3 cm more than the comb protrusion. Fastening steps to risers and stringers is carried out on self-tapping screws, the caps of which must be recessed into the tree.

Kosour fastening to top floor. Ways to connect the elements of the stairs.

Kosour fastening to top floor. Ways to connect the elements of the stairs.  Attaching the kosour to the floor

Attaching the kosour to the floor Installation of fences

You can give the structure a complete look with the help of auxiliary parts. For this, carved, straight, figured wooden and metal fences can be used.

Installation of pillars with balusters is considered challenging task where precise marking with a fit is required. In the step, a dowel hole is marked at a distance from the edge equal to ½ the width of the baluster base. Then holes are made on the steps and dowels are glued into them (they should protrude 1-1.5 cm from the surface).

After that, according to the diameter of the dowel, it is necessary to make holes at the base of the pillars and balusters, coat them with glue. All elements are mounted on dowels with vertical adjustment. Next, prepare the handrails by cutting the edges at the right angle and milling them from the underside. For docking with supports, holes are drilled on the cut of the element. The handrail is installed on a dowel glued into the support post.

After the glue dries, the stairs must be covered with an antiseptic primer, then the surface is treated with transparent or paint. Can be put decorative plinth. In a spiral staircase, you can decorate with an axial support in the form of a log or beam, install a bent bowstring to support the steps. The price of such a design will be high, since viscous flexible wood is used in production, but the final effect is worth it.

The material from which the stairs are made can be different - wood, iron, concrete, or a combination of these materials. But most often, wood is used to build stairs.

Any structure must be safe for movement on it. To do this, before building a staircase, it is necessary to perform its calculations, based on what type of staircase design is expected.

To calculate a wooden staircase, do the following:

- Determine the height of the interfloor space, from floor to ceiling, taking into account interfloor overlap, and determine the area that will be allotted for the stairs.

- Determine the number of steps in a staircase based on their tread depth, riser height, and stair angle. Usually the height of the riser is 150 - 200 mm, and the optimal width of the riser is usually 250 - 320 mm.

- It should also take into account the height of the clearance between the horizontal plane of the steps and the bottom ceiling structure, this is necessary so that a person, when going up or down the stairs, does not touch the ceiling structures with his head.

General examples of drawings for a wooden staircase

Before making any drawings in dwg format, you must select the type of stairs.

It is necessary to perform certain measurements and calculations, and determine the general parameters of the stairs:

- The angle of the stairs, this parameter is usually in the range of 23 - 37 degrees.

- The minimum height between the ceiling and steps must be at least 2 m.

- The width of the stairs itself must be at least 1 meter.

After determining all the parameters, you need to draw a plan of the room, on which it is necessary to mark the location of the stairs and all its dimensions with reference to the room plan. Separately, it is worth making a general drawing of the entire staircase for a better understanding of all the necessary parameters.

All drawings can be made by hand, but in order to avoid mistakes, it is best to make all drawings online using a special calculator.

If a person finds it difficult to independently create a drawing of a staircase, you can use ready-made drawings and diagrams of stairs by printing them and choose the best option. But, it is necessary to do this even at the stage of building a house, since it will be difficult to select a drawing for a finished building.

Detailed and general description of the online calculation of wooden stairs

To calculate all the necessary parameters for creating with your own hands, you need to take all the dimensions, such as the height between the ceilings, the area that will be allotted for the stairs, its angle of inclination, the length of the opening, the number of steps.

To calculate the stairs made of wood, it is best to use special online calculators or with special utilities:

- Various utilities also allow you to calculate, view, including in 3D format, and, if necessary, edit everything, and redo all diagrams and drawings. It is possible even in similar utilities create a diagram of the whole house, as well as draw a staircase and see how everything will look on a virtual layout.

- When, you need to decide on the type of stairs, it can be single-flight, double-flight, spiral, stairs with a 180-degree turntable, etc. and each type of stairs requires its own calculation.

That is why you should use special online calculators or special utilities, which are much more profitable and easier even for novice builders.

The basis of the drawing for a ladder made of wood

The main advantage of a wooden staircase is its relative lightness, environmental friendliness, besides, wood is easy to process, and a wooden staircase will look optimal in a country wooden house.

But, before you make a staircase to the second floor of the house, you need to make a drawing of the stairs, which will take into account all the parameters:

- Based on the drawings, the marking of wooden blanks is made, from which the staircase will subsequently be assembled. All dimensions that will be on paper are transferred to blanks, and they are sawn according to the markings.

- But, before you make drawings and engage in sawing the material and subsequent assembly of the stairs, you should evaluate your strengths, since not everyone can correctly draw up a drawing and correctly cut all the material.

Before making a drawing, it is necessary to measure the place in the room where the staircase will be located. This is the height from floor to ceiling, the width of the ceiling, you should also take into account the type of stairs, the angle of its inclination, the fastening system, etc.

Without these data, it will be almost impossible to make a drawing of a staircase, and even more so, to make it.

The principle of drawing up a drawing of a wooden staircase to the second floor

Houses are built two-story, three-story, and, to move between floors, it is necessary to equip a staircase.

The manufacture of any staircase begins with determining its type, it can be:

- Spiral or spiral staircase, single-flight classical staircase, double-flight with a turn, etc.;

- Also, the staircase, in addition to its main function of lifting or lowering, can be almost invisible in the room, or, on the contrary, stand out in the interior, and even serve as a decorative decoration.

Therefore, before you start, you need to select its type, after that you should schematically draw a house plan, the staircase itself and see how this or that type of staircase will look on the diagram. If everything suits a person, you can start creating detailed drawings of the stairs.

When creating a drawing, one should take into account all previously made measurements, the angle of inclination, the width and height of the steps, the width of the staircase itself, if it is supposed to make a fence, then it should also be shown in the drawing.

Schemes and drawings for the manufacture of wooden stairs with their own hands

The staircase is an essential element of houses, it provides a connection between floors, and the staircase must also provide comfortable movement along it, be safe and fit into the interior of the room. Plan and build a staircase should be based on building codes, and an accurate calculation and drawings are also necessary, since if this is not done, then later, during manufacture, errors may be detected.

The nuances that will prevent the redoing of the entire structure, the unnecessary consumption of materials and time:

- Before creating drawings, you need to decide on the type of stairs, see different examples, and choose the one that will most fully satisfy all the requirements. After that, you can start creating drawings, and plan the arrangement of the stairs in one place or another in the house.

- Before creating a drawing, you must first measure, this is the height from floor to ceiling, taking into account the interfloor partition. And also calculate the number of steps, their width, height and angle of inclination of the stairs, etc.

- The drawing should not only display all the dimensions of the stairs, but also indicate the fences, their height.

It is also worth drawing a general diagram of the house, which will display the location of the stairs indicating the area occupied.

Such a scheme will allow you to better understand what the finished staircase will look like, and will allow you to double-check all the calculations before making the stairs.

It is best for a novice builder based on drawings to start making the most a simple staircase using a carrier beam - kosour. Their number in the ladder can vary from 1 to 3.

Do-it-yourself staircase made of wood: calculations (video)

During the construction of a multi-storey building, it is necessary to equip the stairs so that you can get from floor to floor comfortably and safely for the health of residents.

Most private houses in our time have several floors. It is cheaper to build such a house, since you can get more living space with a smaller foundation. After all, it is the foundation that accounts for the main expenses during construction. Yes and organize convenient layout two-story house easier.

But the presence of more floors requires the construction of stairs, which often frightens those involved in the construction of their house or cottage. To them, such work seems to be something complicated, but in fact, everything is quite simple. Good ladder easy to build with your own hands, just knowing a few features.

What is the staircase made of?

Stair elements

Stair elements First you need, of course, to understand what it is, what are its main elements. The fundamentals of the design here are so simple that the differences between different types minimal.

First, everyone knows that it consists of steps. It is on them that the main burden falls. The steps do not hang in the air, they rely on one of two types of supporting structures - bowstrings or stringers.

- Bowstrings are two thick boards in which special grooves are cut for steps and risers. Such grooves are made according to the template. The bowstrings are pulled together with strands of both metal and wood;

- Unlike bowstrings, stringers are not straight boards, but have a sawtooth shape. Horizontal cuts are used as a support for the steps, and vertical cuts are used to fasten the risers. Another difference between the kosour and bowstrings is that during construction, you can use not two boards, but one. In the latter version, the steps rest on the walls.

Kosour marking scheme

Kosour marking scheme Optional, but present almost everywhere, the element is the risers. Their main function is decorative. Risers make it possible to hide inner space stairs.

Railings that increase the level of safety of use are also not required, but highly desirable. Sometimes stairs have elements such as a support step or special platforms.

What are stairs

Most modern houses they make one of their three main types - marching, on the bolts, screw. At the same time, they choose based on aesthetic preferences, the availability of free space in the house, budget and other parameters.

Marching stairs

The most common marching stairs

The most common marching stairs The simplest and most common design is the marching staircase. Although, having such an important plus - ease of construction, it also has one important drawback - it takes up quite a lot of space. As a result, its construction may not be justified in a small house.

Depending on the number of storeys of the building, its size, stairs of this type are built single-flight, two-flight, three-flight, etc. Marches are called separate segments, which may consist of a different number of steps, but usually no more than fifteen. The optimal number is considered to be ten steps.

In addition, they are divided into open and closed. In most cases, owners make a choice based on aesthetic preferences, because the only difference between them is the presence or absence of risers. Open marching stairs are chosen by those who want a feeling of lightness in the interior.

They have a similar device. They also differ simply in what kind of support they use for them. They can rely on bowstrings, or they can rely on stringers. At the same time, there is no total preference for one type of support. It all depends on the wishes of the owner or location. For example, for a staircase against a wall, it is quite logical to use a stringer as a supporting beam.

To save space, they are often made with a turn. In this case, trapezoidal rotary steps, called winders, are used. The most common angles of rotation of mid-flight stairs are 90 degrees (quarter-turn stairs) and 180 degrees (half-turn stairs). They also come with a 360-degree rotation, but then they can also be attributed to screw ones.

Bolts stairs

Stairs on the rails have a modern, technological and light look.

Stairs on the rails have a modern, technological and light look. With the growing popularity of high-tech or modern interiors, the popularity of stairs on the rails has increased. They really have a modern, technological and at the same time light look. They got their name from the German word "bolz", which means "bolt" in translation, this is the name of their main structural element - large hinged balusters.

The design feature here is the absence of a frame, which creates the feeling that it is floating in the air. Its role is assumed by the steps and the bolts, mounted to the handrails.

There are several types of designs of stairs on the rails. You can choose either one that involves only the use of balusters, or with one side resting on a wall, bowstring or stringer. Combinations are quite common. The choice depends only on the taste and planning features of the house.

In addition to aesthetics, they have one definite practical plus - high maintainability. Any element, from steps to railings, is very easy to dismantle.

Spiral stairs

Spiral staircases are popular both in modern and in classic interiors

Spiral staircases are popular both in modern and in classic interiors

Both in modern and classic interiors, spiral staircases are popular. They are valued primarily for the fact that they take up very little space (example in the photo). If you have a small house, then this is the choice for you. Their compact, space-saving proportions make efficient use of space. On the other hand, it was not without drawbacks - they are not wide and steep, and self-mounting, although not very difficult, requires more work than in the case of marching ones.

There are two main designs in use today:

- The first of them involves the use of bent-glued handrails, on which the steps are attached. This design is quite complex, but it is also distinguished by its special beauty;

- The second, the most common and classic, involves the use of a central support and curved handrails. Steps are attached both to the support and to the handrails. This design is simpler and does not have such strict requirements for the strength of materials as the first one.

Design spiral staircase can also provide for the support of steps on the wall. In this case, special recesses are made in the wall, to which they are attached. It will not necessarily be circular, it may well be polygonal.

Make a ladder: Requirements

You need to design a staircase at the design stage of the whole house. In this case, you need to take into account a few simple conditions and requirements:

- It is necessary to consider where it will be installed;

- How many tenants and how often they will use it, and how old these people will be;

- Will it be necessary to carry something very heavy along it;

- It is required that the slope angle not only does not exceed 42 degrees, but is also constant along its entire length;

- The minimum width should be 80 cm and not less;

- Steps should be installed on the basis of a minimum design load of 200 kilograms per meter. cube;

- The minimum design load for the railing is 100 kg per meter. cube;

- Stair railings should not be too low. Their smallest height can be at least 80 cm;

- Balusters should not be too rare, the clear distance between them should not exceed 15 cm.

Make a ladder: Calculations

Before making a staircase, it is necessary to correctly make calculations

Before making a staircase, it is necessary to correctly make calculations Taking into account all the above requirements and choosing the appropriate type of stairs, you can safely proceed to its construction with your own hands according to the drawing.

The success of independent construction depends on correctly made calculations. Calculating the design parameters of the stairs, you determine those dimensions that best contribute to ensuring convenient and safe movement. Moreover, convenience is supported by a certain ratio between the rise and advancement.

When designing, you need to remember that all steps of one march must have the same dimensions. At the same time, the sum of the double height of the riser and the step should not be less than the length of the average human step, which is 60–66 cm.

To achieve the greatest convenience, it is worth maintaining the difference between the width of the step and the height of the riser at the level of 12 cm, but the greatest safety is achieved when the sum of these parameters is not less than 46 cm.

When calculating the angle of inclination, it is taken into account that the distance from the plane of each step to the ceiling should not be less than two meters.

The optimal angle is considered to be in the range from 23 to 37 degrees.

Naturally, the larger it is, the less space the structure will take, but at an angle of more than 45 degrees, it will simply be inconvenient to climb along it.

In order to determine the total length of a simple flight of stairs, you can use the formula H2 + D2 = L2, where H is the sum of the distance from the floor of the first floor to the ceiling and the thickness of the interfloor ceiling, and D is the size of the projection onto the floor. In order to determine the size of the projection, you must first find out the number of steps required. To do this, divide H by the selected step height. After that, the resulting number of steps is multiplied by their chosen width.

Make a ladder according to the instructions: a ladder with bowstrings

There are many types of stairs, now we will talk about the stairs on bowstrings.

Staircase to the second floor on bowstrings

Staircase to the second floor on bowstrings How to make a string

It is necessary to start building a staircase on bowstrings from their manufacture. Why choose either a solid solid and fairly thick board or a durable glued laminated timber. The length of the boards is selected based on the length of the stairs or march. You also need to prepare the strands with which you fasten the beams so that they do not part in different directions during operation.

The markup is done even before the bowstrings are installed. This stage plays an important role, since its incorrect execution often leads to a banal distortion of the steps. In order for the cutouts of the grooves to be completely identical, located equidistant from each other, a self-made template is used when marking. A thin sheet of plywood is used as a template.

On the inside of the board, you need to draw a boundary line, stepping back 5 cm from the edge, otherwise the bowstring has a chance to turn into a string.

It is these lines that will act as the border of the steps. Then they take a template, apply and outline the places for future grooves, moving to the end. The location of the grooves on the beams of the bowstrings should be mirrored.

Mounting the bowstring

Mounting bowstrings does not require any special skills and a lot of time. The whole procedure consists in the fact that the bowstring is fastened with screws to the floor and the ceiling of the floors. Sometimes, if a very large load is expected, support beams are used. But such a design is rarely found in interiors, due to its bulkiness and lack of practical necessity.

Cutting elements

For cutting grooves, a conventional milling machine is used. This requires two or three approaches, no more. They almost always start with side cuts, after which they make additional ones that make work easier with a chisel. The optimal depth is 1.5–2 cm. At the end, the grooves are cleaned and the edges are smeared with glue before mounting the steps.

How to make steps and mount them

Making steps is one of the simplest procedures among all installation work. A dry board is taken. Its thickness should be at least 3.5 cm. The width must correspond to that which was chosen for the steps in the calculations. The board is cut based on the width of the stairs, including the railing. Grind after cutting. The procedure for making risers looks almost the same. Unless you can use a less thick board - up to 2 cm.

When assembling a flight of stairs, the steps are first of all attached, for which self-tapping screws are used. Best Option are self-tapping screws 6x90, of which there should be six pieces.

It is also possible to mount without the use of additional devices, but only with glue. But its strength depends on how tightly the step fits into the groove.

Sometimes the steps are attached to the bowstrings without using grooves. Then, surfs or bars are attached to the inside of the boards with the help of metal holders, on which the steps are placed. Risers can be attached to bowstrings with or without screws.

How to make railings and mount them

Railings can be either made independently or bought ready-made. Although they may differ from each other appearance, their design is the same - the railings consist of handrails and balusters. Handrails are usually made from boards, and balusters are usually made from square bars. Moreover, the latter can be both very simple and carved.

The number of balusters should usually correspond to the number of steps. Two of them, installed at the beginning of the stairs and at its end, play the role of support. All the rest are decorative.

They also help safe use design. Self-tapping screws act as fasteners, which can be hidden with a decorative plug. After fixing the balusters, handrails are attached to them. For this, self-tapping screws are also needed.

Staircase on stringers

Staircase to the second floor on stringers

Staircase to the second floor on stringers The manufacture of a stringer is in many ways similar to the manufacture of bowstrings, although these two types of support structures use a slightly different principle for holding steps.

Using this technology, temporary, outdoor (street) home-made stairs are made in houses.

You need to choose a solid board of solid durable wood. The board must be dry.

After that, a marking template is made, similar to the one used to make the bowstring. The template imitating the protrusions must correspond to the calculated dimensions of the steps. This time you do not need to draw an indent line, since it will not be necessary to cut out the grooves.

For sawing out protrusions, it is most convenient to use an electric jigsaw. After they are sawn, they need to be sanded.

Self-manufacturing stairs at first glance may seem like a rather complicated task that requires calculations, right choice material and skills. But this is only at first glance. It is enough to get acquainted with how everything is done to understand that there is nothing complicated here.

Making your home comfortable does not require too much time, or too much effort, or a significant financial outlay.

There are also types of stairs for limited space - folding, retractable, cabinet stairs. They are temporary and are made mainly of iron.

Video

Watch a YouTube video on how to make a ladder with your own hands.