Do-it-yourself fireplace from cardboard boxes. DIY fake fireplace: ideas for making and decorating

According to a long tradition, would you like to hang it on a fireplace, but it is not provided for in your apartment? No problem! We will tell and show how easy it is to make an incredible - decorative false fireplace made of cardboard.

On the eve of the New Year, we are trying with all our might to create coziness and comfort in the house and festive mood. For many, such New Year and Christmas comfort is associated with beautiful fireplaces, which we now and then see in the pictures on Instagram. But our city apartments are not equipped with such structures. But you really want such a fireplace for yourself, so that you can hang Christmas socks there and put gifts there. But do not get upset ahead of time, because decorative fireplaces are no worse than real ones, and you can make them in a matter of hours.

A decorative false fireplace for the New Year can also be made from cardboard sheets with wooden elements that will support the structure. Use decorative moldings and skirting boards to beautifully decorate your handmade fireplace.

"Flame" for a fireplace made of cardboard boxes

What is a fireplace without fire? And although you can’t make a real fire in a decorative fireplace from boxes, you can use several interesting ideas to simulate a flame:

- draw a fire on a piece of cardboard, cut it out and place it against the back wall of the firebox;

- roll up a luminous garland into a ball and put it in the fireplace;

- put real or cardboard logs in the fireplace and wrap them with an LED garland.

Watch an online video on how to make a New Year's fireplace from boxes and foam with your own hands

Now you know how to make a fireplace to create an interesting piece of furniture. It remains to decorate the fireplace as you wish, attach garlands to it, Christmas decorations and wait for the New Year and Christmas.

In a city apartment, where, due to the lack of chimneys and reliable heat-insulating ceilings, it is impossible to install a fully functional wood-burning fireplace, it is possible to design its decorative model. When using inexpensive improvised materials, the work will not require great skills in construction and expensive tools. A do-it-yourself cardboard fireplace is built in a few hours, but it looks no worse than the real one.

Children can also be involved in the work, for them this activity will be not only interesting, but also developing.

There are several models according to the location in the room:

- wall-mounted - located near the wall and protrudes with its facade for a certain distance;

- built-in - mounted directly into the wall;

- corner - occupies the corner of the room;

- island - does not adhere to the wall and is most often installed in the center of the room.

False cardboard fireplaces are most often made wall or corner, because they are not intended for heating the house, but have a decorative function. Another such dummy can be used as furniture: shelves can be installed in a niche, and the top tabletop will play the role of a shelf for small items.

photos

According to their external design, there can be a huge number of types of false fireplaces: in the English, classic, rustic style, with an arch-shaped or rectangular firebox, with a model of a woodcutter or oven. When designing, it is important to consider that this detail is combined with the surrounding interior.

photos

The simplest option that children can also make is a small model without a chimney with a rectangular portal and a firebox. Outwardly, it will resemble a large letter P. In the future, this decorative fixture can be supplemented with other elements and make a more complex decor.

It is possible to assemble a model of a classic English fireplace from cardboard. It features an open trapezium-shaped firebox and a straight chimney leading up to the ceiling. Inside the furnace niche, the walls are located at a small angle of about 20°. The English version is decorated with decor that imitates limestone, rubble or brick.

A dummy that imitates a sauna stove or a rural style should have an arch-shaped firebox. Making a figured hole out of cardboard is not difficult. And it is best to finish it outside with cardboard or foam stucco molding in the form of bricks or cobblestones.

Material and tool

Getting thick corrugated cardboard is not a problem, you can use containers from large household appliances: TVs, refrigerators, washing machines or other goods. The entire manufacturing process can be done at home right at the place of the future location of the decorative hearth.

Corrugated cardboard is good because, thanks to internal stiffening ribs, it retains sufficient strength, while it weighs very little, and is cut with a simple clerical knife. But a cardboard fireplace, even with exterior trim, will not withstand big weight so do not place heavy objects on it. It is not waterproof and high temperature, therefore, a false fireplace should not be located near heat sources, and only safe methods should be used to simulate fire.

To work on the construction of the frame, you will need the following tools:

- stationery knife;

- polymer glue;

- transparent tape;

- pencil;

- roulette;

- ruler.

Depending on the ways decorative finishes cardboard false fireplace may need the following materials and tools:

- paint or decorative putty;

- paint brush or spatula;

- paint trays or a container for mixing putty;

- corners, moldings, moldings, frames or profiles.

You can decorate such a hearth with putty and subsequent painting, or stick ready-made stucco, polyurethane sheets, self-adhesive laminated paper with a wood texture or natural stone. Based on the chosen method, the appropriate set of items for decoration is selected.

Plan and calculations

Even the simplest version of a cardboard fireplace needs a phased work plan. It includes the following items:

- determining the shape, type and location of the fireplace;

- the choice of materials for the frame and decorative finishes;

- creation of a design drawing with dimensions;

- preparation of tools and materials;

- marking on cardboard parts of the frame;

- cutting of elements, their gluing and installation;

- exterior finish.

The development of such a plan is good because by performing all the steps step by step according to the existing scheme, you can gain some experience and next time start creating a more complex structure, for example, from polyurethane or plywood. Despite the frivolous work of gluing ordinary cardboard, you can make a detailed calculation of the dimensions of the firebox, portal and chimney, as for a real wood-burning fireplace. This is useful for gaining some experience in construction.

frame

Worth Considering step by step instructions to create the most common frame layouts: wall-mounted U-shaped and corner raised fireplaces.

For a wall-mounted fireplace, you will need a wide cardboard box with a height and width of 1 - 1.4 m and a thickness of 0.2 - 0.25 m, for example, from a large LCD TV. First of all, the fold and cut lines are marked on the cardboard with a pencil. A rectangular symmetrical cutout is made in the center on the front side - this will be the furnace portal. The back of the box remains intact. For greater rigidity, the inner walls of the firebox are glued inside. All sides of the frame can be fixed with plastic corners or moldings. The frame is placed on a foam or polyurethane base.

For finishing the U-shaped version, it is best to use light ceiling panels white color or self-adhesive laminated paper. Styrofoam panels are attached to a waterproof polymer adhesive that dries in minutes. Another way of finishing is the use of water-based paint. In order to keep it firmly on the cardboard frame, you can first smear it with a primer or a very thin layer of liquid putty. After that, wait 1 - 1.5 hours for the primer to dry completely and start painting.

Corner decorative fireplace from a cardboard box is made in the form of a prism with triangular base. The corners of the frame are tightly glued with adhesive tape or polymer glue, an arch-shaped hole is cut out in the front part, the top can be decorated with a decorative tabletop made of lightweight material, such as PVC or laminated plywood. Inside the firebox for beauty, false walls should be made from the same cardboard.

The decor of a corner cardboard fireplace can be done in the same way as the previous version: painting or appliqué. In a niche, you can place beautiful souvenirs or a toy fire, the creation of which will be described in the next section.

Portal

fireplace portal- the part where the burning of firewood takes place. In the case of imitation using cardboard, there are several ideas on how to make it look as realistic as possible and look like a real hearth. First, it is worth installing a fake firewood grate inside. Since in the present version it is metallic, it is necessary to look for light materials that are visually similar to metals. It can be plastic or wooden details covered with shiny mastic or foil. You can use black paint.

Next, we make an imitation of a flame in the furnace of such an imaginary hearth. There are several ways to create the illusion of a bright, flickering fire. The simplest and safest technique is based on the use of a New Year's garland. First, artificial firewood is made from dry branches. They are covered with cotton wool and foil. Next, a bundle of such firewood is placed in a circle of stones in a fireplace niche, and a garland folded into a ball must be inserted into its center. When connected to the mains, a fascinating flicker is created inside the fireplace, similar to smoldering real firewood.

A garland or individual light bulbs can be placed in raw salt crystals. They create beautiful effect flicker and also have a beneficial effect on the body. It should only be taken into account that the construction of the cardboard fireplace can withstand the weight of salt lamps.

On the floor at the base of the firebox, some people place a flat display on which a picture of a live fire is transmitted. This method is beautiful but impractical - to use an expensive monitor for only one image. But it is quite suitable for one-time use, for example, on New Year or other holiday.

A simpler and cheaper method of simulating a flame is using a hand-drawn picture, embossing, appliqué or a volumetric hologram. This technique can be constantly changed, creating new original images.

Nowadays, almost every person dreams of a cozy and warm home. When we say “home”, we often mean the family hearth. Thus, the idea of \u200b\u200bcreating a home with your own hands arose. For most, comfort is associated with a fireplace, but many do not have the opportunity to install it. However, not everyone knows that it can be done independently and not with the help of brickwork but from simple cardboard boxes. Do not listen to those who will claim that he is not real. This can be done in one day, and outwardly it can become even better than the original.

Our country can boast of a great ability to produce masterpieces from improvised means. In this case, we will consider fireplaces, the manufacture of which will take a little time. The most important thing, without which a false fireplace will not work, even with the most detailed instructions It's a big cardboard box. It can be taken from the TV, the refrigerator and even from the vacuum cleaner.

But the most important thing is that it must meet 3 requirements:

- The cardboard must be packing and very strong. It must be rigid to support the weight of the top shelf and future finishes.

- The box should be large in order to have a lot of room for fantasies. If the box of the required parameters was not found, you can use smaller dimensions and create a corner fireplace.

- The material must be irrelevant. For example, if you bought a refrigerator and the warranty period for repairs has expired, you can use the box for your own purposes. Otherwise, if the equipment breaks down, it may not be accepted for service.

In addition, for work you will need: masking tape, thermo-glue, primer, stationery knife, spatula right size, acrylic paint. If you want to organize additional finishing, you can purchase foam, drywall, mosaic borders, varnishes and grout. In order to make the work more comfortable, you can use a grinder and a jigsaw.

Preparation before creating a fireplace with your own hands from the boxes

Before creating an artificial cardboard fireplace, you need to create a design for the upcoming product. You need to create it because in the process even the most skillful hands will not be able to work only on fantasy, you will need to rely on at least something.

If you do not have a box of the right size, you can use several pieces of small boxes and glue them together in the process, giving the assembly an arched shape.

The preparation of the plan should first include marking the parameters of the future fireplace. Everything must be taken into account according to the possibilities of the room.

When calculating the parameters, the following conditions must be taken into account:

- The fireplace should be placed under a wall that has no furniture on it. Thus, it can become a key attribute.

- If there is little space, but there is an empty corner, then a small corner fireplace would be a great option. He can effectively decorate the living area.

Having calculated all the dimensions and determined the free space, you can begin to organize the layout of the future fireplace. On a large sheet in a selected scale, you need to display a plan in height and width. Do not forget to indicate the depth of the furnace part, as well as its shape. After all the details are specified, you can proceed directly to the work itself with the box.

Do-it-yourself New Year's fireplace: we make a frame

Creating a fireplace frame is the most crucial moment in organizing a cardboard fireplace. To do this, you need to make a markup on the box and use a clerical knife to cut out all the components for the future design. The future will depend on how accurately the work is done. appearance products. Therefore, the work must be done as accurately and accurately as possible.

In order for everything to go perfectly, lay the material on the floor and use a pencil to mark the place of the future firebox and all the necessary bends.

Markup is best different colors. This nuance will help in the collection of structures.

In order for the cardboard to bend better during assembly, it is recommended to cut it, but only slightly and the top layer, which covers the corrugated inside.

After that, the firebox is cut out. Regardless of what shape the future firebox will have, its formation is always identical. First, a window is cut out, then it Bottom part bends, and thus we get the bottom of the firebox. The next thing to do is the side and back walls. They are measured and cut from another piece of cardboard identical in shape in the frame. Each of the cut out figures should be 5 centimeters larger. This is done so that the material can be easily glued. The whole structure is assembled and glued to the mounting adhesive or fastened with a stapler. If you want to install additional shelves, then the assembly of the structure should be postponed until they are made. The shelves are made in the same way as the fireplace insert.

When everything is ready, you can think about strengthening the structure.

To strengthen you will need:

- Styrofoam or cardboard should be placed under the furnace and shelves;

- The material must be dense, light and able to withstand everything that will be placed in a niche;

- If there is a possibility that the structure may bend in certain places, you need to put it rolled into a tube in cardboard.

In order for the structure to be more durable, experts recommend using cardboard or plywood. But such materials require installation only on a metal frame.

Error correction or how to make a fireplace out of boxes correctly

If you have finally created your masterpiece and the false fireplace is ready exactly according to the scheme that you created, but as a result there were several shortcomings, they must be eliminated. This is where regular putty can come to the rescue.

Work with putty carefully, in parts and in small areas. Do not forget that the cardboard strongly absorbs moisture and a second layer should be applied only after the previous one has dried.

There is a little trick that can help out in minimal damage. You can use a standard rough patch. It adheres well to cardboard and putty adheres remarkably well to it. On the Internet you can find a master class, which has step-by-step instructions with photos and videos to correct all errors.

False cardboard fireplace: decoration and decoration

Have not yet invented a fireplace that would be without a lid. And this fireplace is no exception. It must be made of dense material. It can be foam or drywall, you can make it from plywood. First, cuts must be made in it so that the panel falls into place without flaws. Check that the notches match and attach the lid to our fireplace with glue. The joints can be masked with putty.

And the last step - finishing. Initially, the finishing putty is applied using a spatula, and then fantasy comes into play. To start our new homemade fake fireplace wrapped with paper. The decor of our fireplace can be organized with foam borders, which are very often used to decorate the ceiling. You can also create decorative rock, which is painted under a decorative stone. The cover will look great if it is tiled or decorated wooden clapboard. You can complete all the splendor by varnishing in order to fix and save all the design.

Do-it-yourself cardboard fireplace (video)

The fireplace, as it turns out, is very easy to make with your own hands simply using cardboard boxes. And so that you do not have any difficulties, the most key points were disclosed in this article. Use step-by-step instructions, connect your imagination, and you can create a real family hearth in any room near which all household members can gather.

If you can’t build a stone or brick fireplace, we recommend that you stop at the cardboard version of the fireplace. This fireplace is perfect for both private houses and apartments, it is easily transferred from place to place and does not require any special material investments for its construction. We will learn how to make a fireplace out of cardboard boxes with our own hands further.

Do-it-yourself New Year's fireplace from cardboard boxes

With the help of a fireplace, it is possible not only to decorate the home before the holidays, but also to create a real New Year's mood. In appearance, such a fireplace is no different from the real one, its only difference is the fact that the fireplace is not able to heat the room.

Before you start making a fireplace, determine its location. If there is not much space in the room, then it is best to stay at corner version fireplace. Also, decide on the size of the future design. In this option, you need to proceed from the size of the boxes from which the fireplace will be built and from the size of the room.

In the process of working on a decorative fireplace made of cardboard boxes, you will need:

- large cardboard boxes;

- glue, for connecting boxes together;

- polymer-based adhesives;

- paints for working with cardboard surfaces, most often, it has a water base;

- colorless lacquer;

- paints of golden color in a can;

- molding for the ceiling;

- brushes and sponges;

- masking tape;

- rulers, levels, measuring instruments.

Among the main parts of the fireplace, we highlight: the base, the portal and the top cover.

For the manufacture of the main part we use cardboard. The width of the base is about 50 mm and the length is about 120 mm. From a cardboard box, it is necessary to build the main part and glue it with adhesive tape. Thus, it is possible to obtain a blank in the form of a dollhouse.

For the manufacture of a portal under the fireplace, cardboard is also used. We recommend staying on the option that has a solid back wall. For the manufacture of the front part, a cardboard cut in the form of a strip is used. Next, you should take care of cutting out the furnace part, the size of which is smaller than the fireplace itself. To connect all the parts together, use adhesive tape.

This is followed by the process of manufacturing the top shelf, its quality determines the strength of the fireplace. Therefore, if you plan to install some heavy objects on the fireplace, then take care of the strength of this base. To do this, you need to connect several layers of cardboard together. To connect the parts, in this case, use PVA glue. After that, the product can be pressed until completely dry. Thus, it is possible to create a rigid shelf located on top. To fix the shelf on the portal, use a polymer-based adhesive. Next, using masking tape, glue all the joints between the parts on the fireplace.

The easiest and most enjoyable moment in making a fireplace from a cardboard box with your own hands is the process of decorating it. To frame the product, use moldings or baguettes made of foam. It is possible to create stucco molding. Next comes the process of painting the fireplace. Initially, the product should be given the same tone, most often, it is covered with light-colored paint. In order for the coloring composition to be evenly absorbed into the fireplace, we recommend applying it with a brush. To paint over stucco and other relief elements, use a sponge.

Further finishing of a fireplace is carried out by means of a transparent varnish. This material will allow you to securely fix the first layer of paint. In order for the fireplace to have a more realistic appearance, it is necessary to cover it with gold spray paint. For additional decoration of the fireplace, hang New Year's socks, tinsel, garland on it. In addition, wallpaper can be glued inside the firebox that imitates brickwork. Please note that the use of burning candles for decoration is unacceptable, since the fireplace is made of cardboard and will easily catch fire from minimal contact with fire.

As an additional accessory for the New Year's fireplace, we recommend using self-made firewood. For their construction, you will need:

- corrugated cardboard;

- polymer-based adhesives;

- paints;

- scissors;

- masking tape.

Roll the cardboard into a tube, use masking tape and glue to fix it. The length and width of the logs should be different, cut a small log into pieces and connect it with a large one, making an imitation of knots. After the glue dries, paint the logs white.

DIY decorative fireplace made of cardboard boxes

Before starting work on a decorative fireplace, first of all, you need to determine the size of the fireplace. Please note that the fireplace should be located in a prominent place that will make it a central and attractive part of the interior.

In order to determine the size of the fireplace, you must use a tape measure. In relation to the place of installation of the future structure, its dimensions are determined.

Particular attention should be paid to the process of finishing a decorative fireplace. It should exactly resemble a real fireplace made of brick or stone. At the next stage of work, material for work and tools are selected. The body part of the fireplace is recommended to be made of cardboard on a corrugated basis, from under large household appliances. These boxes are highly durable and are ideal for creating a fireplace.

In addition, for work it is necessary to prepare PVA glue and a polymer-based composition. In order to paste over the corners and other elements of the fireplace, use masking tape. In order for the fireplace to acquire the same color, white paint is required. In some cases, a clear lacquer will also be required. For getting different colors paints, prepare colored dyes, with their help you can achieve a variety of shades when decorating a fireplace.

Additionally, you need to purchase elements in the form of moldings, corners, which will give the fireplace a complete look. In the process of finishing, you should use figured polystyrene foam and polyurethane parts.

In addition, you should prepare a tool in the form of brushes and sponges, pencils and a level. Stock up on clean rags to remove paint or glue from the surface.

We bring to your attention the two most common options for fireplaces:

- wall-mounted;

- fireplace located in the corner.

The fireplace, installed near the wall, is compact in size; various decorative details are installed on the mantelpiece. The wall fireplace is the central part of the room, it is always in a conspicuous place and attracts attention. In the process of making such a fireplace, you should free up space in the room to create it. Further, we recommend that you acquire sketches of this fireplace, all the details of which are placed on the floor. The main parts of such a fireplace are the base, the portal part and the top shelf.

Let's start working on the base first. It must be rigid and durable. Therefore, ordinary cardboard will not be enough, it is necessary to take care of its compaction with several layers of cardboard. We recommend fixing stiffeners inside the base. This part of the fireplace should be 80-120 mm larger on each side than the product itself. There are two ways to make a base for a false fireplace from cardboard boxes with your own hands:

- manufacturing a box that has sides, installing additional elements on its bottom that increase rigidity;

- the manufacture of several cardboard panels that will serve as the bottom and surface, the stiffeners in this case are fixed only at the bottom.

For the manufacture of the side parts of the base, identical strips made of cardboard are used. Thus, the base becomes more durable. Fixing the strips is carried out using masking tape.

In the process of making the stand, think about how to fix the portal to the surface. Most often, it connects to the bottom. For additional fixation of the portal, ordinary adhesive tape is used.

The next process is the construction of the portal part of the fireplace. For its manufacture, a previously prepared box of a certain size is used. We offer two options for making a portal with your own hands:

- frame base of the portal;

- one-piece construction.

The first option implies a more rigid structure. Since for the manufacture of frame partitions several layers of cardboard material are used at once. Initially, the front and rear parts of the portal are mounted. They increase the strength of the entire structure. On a cardboard base, make markings for the fireplace insert. Use a utility knife to cut it out. Thus, the manufacture of this part of the fireplace is carried out.

To make the ceiling part of the firebox, cut out a small piece of cardboard in relation to its size. Use adhesive tape to secure the part. For additional fixation and strengthening of the main part of the fireplace, use a frame structure in the form of stiffeners.

For the manufacture of frame panels, increasing the rigidity of the base, solid cardboard rectangles are used. They are interconnected with pva glue and dried using a press. This is followed by the process of fixing these rectangles on the front portal.

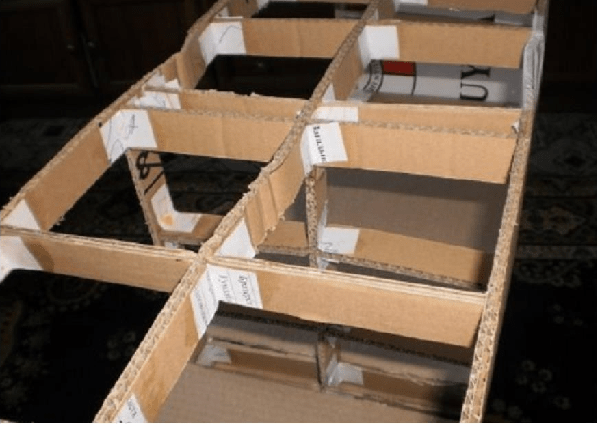

There is another way to create wireframe elements. These partitions lighten the overall weight of the fireplace. They are lattice-shaped. dividing wall. On gratings with increased rigidity, another layer of cardboard material is fixed. The portal is installed on the base of the podium and fixed on it with masking tape or adhesive. After installing the frame, the process of painting and decorating it is carried out.

Fireplace from cardboard boxes photo:

Use painter's tape to hide any seams between the cardboard pieces. Various decorative elements can be installed on the frame part of the fireplace. Please note that in this case, frame walls additionally sealed with cardboard.

The second method of building a Christmas fireplace with your own hands from cardboard boxes is easier to perform. The back wall of such a fireplace will have a solid shape, while it is not possible to equip shelves on it.

To connect the details of the fireplace is also used masking tape. It is enough, according to the sketch, to cut out the furnace part in the box. Rectangular strips are fixed along the side parts of the body. Thus, the formation of the focal part is carried out. Next, fix the finished fireplace mold on the podium. First, the surface is covered with glue, and then additionally fixed with adhesive tape.

The upper part of such a fireplace plays the role of a shelf. Please note that the weight of this element should not exceed the weight of the fireplace, as there is a risk of its deformation. To make a shelf, use several cardboard sheets interconnected. The top layer is used from cardboard with maximum density.

To fix the shelf on the fireplace, use liquid nails. It is possible to manufacture a shelf from a plywood base. In this case, its thickness should not exceed one centimeter. Even better, use moisture resistant plywood.

Decorating a fireplace with your own hands from cardboard boxes

The next stage of work on the fireplace is its decoration. The attractiveness of the finished product directly depends on the quality of its implementation. The first method of decoration involves the use of purchased decorative elements made of polyurethane. To divide the fireplace into several zones, a small molding is used. Next, stucco is installed. It is also possible to manufacture columns.

To fix these elements, use liquid nails. This is followed by the process of painting the fireplace with all the previously established elements decor. For these purposes, we recommend using a sponge and a brush.

Next comes the process additional work over the selection of these elements. For example, stucco can be highlighted with a golden color. After painting is completed, the process of varnishing the fireplace follows, which will prevent damage to the paint. Possibility of imitation brick wall. For these purposes, gypsum-based putty is used.

Additionally, firewood is installed in the firebox, which makes the appearance of the fireplace more attractive and realistic. Installing a garland near firewood will help simulate a flame.

Do-it-yourself cardboard box fireplace video:

The presence of a fireplace in the interior gives the atmosphere weight and a certain significance, style. In our imagination, a fireplace is usually associated with warmth and comfort. In addition, a fireplace is one of the decorative elements, indicating a certain level of prosperity and well-being of the owners of the house.

Important ! In the practical implementation of the idea of \u200b\u200bhow to make a fireplace out of boxes, viewing real buildings with your own hands helps a lot. various options, simple and complex. If possible, look at what a real real construction made of cardboard and boxes looks like, this will make it easier to do it yourself.

Not every owner of a private house can afford a real stove, and one can only dream of a real fireplace in multi-storey buildings. In the conditions of a city apartment, this is often simply impossible for reasons that do not depend on the desire and capabilities of the owners.

In this case, the fireplace from the boxes, assembled with your own hands, will help out. With very little effort, you can decorate your house or apartment with your own hands. original design from cardboard and boxes, which will be a great addition to the festive atmosphere.

You can be sure that making a fireplace out of cardboard and boxes with your own hands will not require a significant investment of time and money. To figure out how to make a fireplace out of boxes with your own hands, not only a person who is well acquainted with the rules of laying a real fireplace, but also an ordinary housewife, and even a teenager can. The main thing would be the desire to work with your own hands with cardboard and boxes. In this case, it is not a sin to participate in a similar event with friends or acquaintances, having received a certain master class and feeling like an expert.

What can a family give a master class in making a fireplace from boxes with their own hands?

With all the "lightness" of the idea of a fireplace made of cardboard and boxes, the manufacturing process gives a chance:

- Raise the mood of yourself and your household with another interesting idea;

- Refresh the interior of one of the rooms of the house or apartment on the eve of the holiday;

- Teach children to put themselves in front of a real challenging tasks and do it by hand;

Getting started, you need to decide on the place where the cardboard imitation will be located. It can be free space against the wall, or a corner of the room not occupied by furniture. With it, you can hide some construction defects in the corner of the room.

Having decided on the place, we measure it with a tape measure with our own hands and calculate the estimated dimensions of the future cardboard layout, whether it can fit in the space allotted to it. It is important to predetermine the dimensions of the cardboard fireplace to the smallest detail so that you do not have to redo the work.

After that, you should decide which option is best suited to the situation, to the style of the interior, view photos of fireplaces from boxes with your own hands on the Web and choose the option that you can make with your own hands from cardboard and boxes.

Make a drawing of the selected option with dimensions and a drawing external design finished product. Calculate with your own hands the need for cardboard and boxes, their sizes. This will allow you to think in advance how the appearance of the fireplace will be designed, what and where decorative decorations will be located.

Before starting, prepare the materials necessary for work:

- Several large cardboard boxes, the more cardboard, the easier it is to choose the optimal shape and size;

- Glue PVA, PVA-M and transparent "Dragon" or "Titan";

- Construction chalk putty;

- Paint on water based, necessarily - white, red and black;

- Long meter ruler, tape measure, corner and construction knife;

- Brush and paint roller for painting the finished product.

For your information ! Before starting work, tune in yourself and explain to your assistants, if any, that making a fireplace from boxes with your own hands requires the highest care and accuracy.

Making a fireplace out of cardboard and boxes

In addition to the decorative function, the wall-mounted fireplace from the boxes can be used as a watch stand, decorative candles or figurines, a bookshelf. Often such a cardboard oven becomes a full-fledged element of the interior of a room as a cabinet or bedside table.

For work, you need to prepare free space so that you can place a large sheet of cardboard and the box itself, transfer the necessary markings and draw the contours of the manufactured product.

If you're lucky to pick up or get hold of a large cardboard box from the TV, washing machine or a refrigerator, the task will be noticeably simplified. Using a ready-made large cardboard box will allow you to refuse to manufacture a supporting frame-frame on your own, which will greatly simplify the work.

Otherwise, for a wall-mounted fireplace from boxes, it is initially necessary to assemble a frame from a building profile or wooden slats, fixing it on the wall at the location of the fireplace. Next, the frame will have to be pasted over with cut-out two or three-layer pieces of thick cardboard, butted together with glue and adhesive tape.

Advice ! Sometimes you have to glue two sheets of cardboard into one "sandwich" with a layer of tape or corrugated cardboard. The base sheet is laid out on level ground, the PVA layer is glued to the bottom and top sheet and the load is placed on top. Such a sandwich turns out to be durable, any element of the fireplace, including the back wall, can be easily made from it.

The design of the fireplace consists of several main parts:

- The body of the fireplace, or a portal of two pedestals, united by a superstructure;

- Fireplace insert - rectangular niche;

- Top shelf or countertop.

As the basis of the fireplace, we put a fiberboard slab, cut to the expected size of the fireplace sole with a margin of 7-8 cm per side.

Cutting the box and gluing the body of the future fireplace

As a basis for the formation of the future body of the fireplace, we use large boxes from household appliances. The cardboard wall of the box has a three-layer structure with layers of corrugated cardboard.

As indicated in the drawing, we mark with the help of a ruler and a corner the location of the firebox and side pedestals of the fireplace from the boxes. We make a T-shaped incision along the axis of the opening of the furnace, turn the formed flaps inward and glue them to the back wall. They will serve to form the inner surface of the opening.

We measure, cut and paste additional elements into the case from the boxes:

- The ceiling of the combustion chamber;

- Internal jumpers in the upper part of the portal and in the side cabinets of the case, this will strengthen the structure and make it more rigid;

All places of gluing cardboard and boxes are additionally glued with sheets of paper, PVA and adhesive tape. At the points of contact of the end surfaces of the jumpers and sheets of cardboard with the body of the boxes, we glue them with our own hands using Dragon glue.

If desired, the back wall of the fireplace can be turned into a storage of the necessary things. It is enough to carefully cut out the windows with a knife, bend the cut out fragment and glue it to the side wall of the box.

The top shelf can be made by hand in the form of a sandwich from two layers of thick cardboard and corrugated tape. Often, for reinforcement, plywood or a plastic cladding panel is put into the design of the countertop, which will allow the fireplace to withstand a significant weight of objects, a vase, or even a TV.

The finished cardboard case is installed on the prepared fiberboard base and glued with adhesive tape from the inside of the structure. The outer joint between the cardboard of the body and the cardboard of the base is glued with paper tape and PVA.

Assembly and finishing operations

After the formation of the main part of the fireplace body from the boxes, they proceed to rough pasting it with paper. At the same time, burrs and irregularities are leveled and trimmed. In places where the joints are glued, excess dried glue is removed and primed.

The next operation will be painting and preparing for finishing. The prepared fireplace body from the boxes is primed in two layers of white water-based paint. In places where the inscriptions of the packaging may show through, glue or apply an additional layer of primer.

The upper part of the portal, especially the attachment point of the top cover and wall cardboard, must be covered with decor. Usually, bovelacci, friezes or foam are used for these purposes. The sticker is made using the "Dragon".

The final operation is the final painting of the fireplace, usually in white or beige color. The inside of the combustion chamber is sealed with panels imitating embossed red brick. On the protruding part of the base of the fireplace, an imitation of rubble stone or molding brick is laid out.

One of the most popular types of fireplace textures is imitation of brick or marble facing material.

As a result, there is a reason to be proud of a do-it-yourself fireplace from boxes.