Do-it-yourself workbench from a bar. Workbench: design rules, manufacturing for all kinds of carpentry and locksmith work

When a major renovation is underway in a home, it is essential that everything is at hand at any time, which will allow you to make the most of your time. To do this, it is important to properly organize the workplace of the home master, if he is used to doing everything with his own hands. During repair or construction, a significant place is occupied by woodwork. However, sawing timber on a stool or bench is inconvenient and long. Rational use of time and resources will help the desktop, also known as the workbench. Make it possible at home.

For most men, the garage is both a "home" for a car, and a storage room and a workshop at the same time.

Not every owner believes that a workbench is constantly needed on the farm: it is needed only for the period of repair or reconstruction of the building, so he prefers to rent it. But such an opinion is erroneous, especially if he is the owner of a household standing on the ground. The carpentry workbench that appeared on the farm will be a real help for him. Having made such a design, the owner receives a number of advantages compared to using a workbench, rented or bought in a building supermarket.

- He will save a significant amount of money, which he can use for further home improvement.

- Gain additional management experience and practical skills.

- Get at your disposal a comfortable desktop, suitable for processing parts made of wood and metal.

- If the owner makes a workbench with his own hands, he can use it at any time.

Therefore, in one room (well, if there is a basement) it is necessary to place racks and a workplace.

Table types

known different kinds workbenches that have different purposes.

- Carpentry workbench for crafting wooden parts. It is convenient to process small wooden products on it, but is not intended for primary processing of wood. For him, you need a countertop three meters long and one meter wide. Details on it are fixed with wooden horizontal and vertical clamps.

- The carpentry fixture is much larger in all respects and heavier. Tree trunks are processed on it, boards, timber and other wood blanks are cut.

- Universal table allows you to work with wood and metal; its table top is reinforced with metal band and has wood and metal clips.

There is a table for locksmith work and car maintenance in almost every garage.

There is another definition of the types of structures according to the possible location.

- Mobile (portable). Used to perform small work with small parts. It is comfortable and light enough. It can be easily moved from one place to another. Is staffed carpenter's table vise of small or medium size, which allows it to be used for small plumbing work.

- The stationary desktop is massive and stable. On it you can engage in the processing of lumber, but home master such a workbench is unlikely to be useful if he does not constantly engage in woodworking.

- Prefabricated on connections using bolts. This is a kind of transformer: at any time it can be supplemented with special equipment and make the necessary changes, depending on the tasks being solved.

And as a rule - it is self-made, that is, made taking into account the characteristics of a particular room.

What type of construction the home master chooses depends on what goals and objectives he sets:

- a desktop is needed for processing small parts and manufacturing small products only for the period of repair and construction work;

- the owner will constantly use it and work with small volumes of wood parts;

- a workbench will be needed to carry out the primary processing of wood, turning it into boards, timber on an ongoing basis;

- it is intended to use the table for occasional processing of small wood and metal parts.

The shape and dimensions are determined by the configuration of the room.

Experienced home craftsmen claim that even a novice owner who does not have the skills to handle metalwork tools can make a product.

The garage workbench is often compared to a desk because it provides the convenience to carry out a variety of jobs and allows everything to be done. necessary tools keep on hand.

Material selection

To make a workbench with your own hands, the master needs wood and metal. If you intend to make a small table, then a wooden base will be suitable for it. Laminated chipboard, pressed plywood with a thickness of at least 5–7 cm is suitable for the countertop. For a stationary table, you can use well-planed boards that are tightly fitted to each other, and partially metal.

In addition to the countertop, it has a large number of shelves and drawers.

And if at the disposal of the home master there is an unnecessary desk, then it will become a good basis. It is also convenient because it already has several drawers or compartments for storing tools.

The workplace of a motorist must be durable and stable.

Will find application in the design old door from a whole canvas. It will make an excellent durable countertop that does not even require processing.

Cabinets with tools and tools must be placed under the table. consumables(drills, hacksaw blades, rags, etc.).

The use of improvised materials available on the farm to make a carpentry table with your own hands will save time and money for the home craftsman.

It is irrational to make a monolithic cabinet out of the table; you need to put your legs somewhere during sedentary work.

You can make your own workbench out of metal. It will be strong, reliable and heavy. But experience shows that an intermediate option is considered the most acceptable, when the frame and cover of the workbench are made of wood, and then sheathed with sheet metal.

However, both sides should be, if not sets of drawers, then at least a set of shelves.

A home craftsman who decides to make a workbench with his own hands will need a certain set of materials. What is needed for this, he knows well.

The workbench in the garage should not be part of the rack, therefore, the wall above it is a place for hanging tool storage.

And for those who do not yet have sufficient experience, we have compiled a list of everything necessary for its manufacture:

- metal corner;

- steel strip and galvanized iron sheet;

- plywood;

- screws;

- anchor bolts;

- square pipe;

- wooden planks ;

- self-tapping screws for metal;

- dye.

Both metal and wooden workbench have the right to life.

What tools will be needed

A self-made small wooden carpentry workbench will take its rightful place in the home workshop. You don't need a lot of tools to make it.

You can always put a piece of plywood or hardboard on a steel sheet, and a galvanized sheet on a wooden surface.

You will need a standard set that can be found in every home:

- screwdriver;

- roulette;

- Bulgarian;

- electric jigsaw or hand saw;

- hammer.

First of all, we determine the ergonomics of the workplace.

Depending on what material will be used for the carpentry workbench, the list of materials and tools may vary. For example, to make a metal desktop, you cannot do without a welding machine and electrodes.

The height of the workbench should be such that you do not have to bend your back, and at the same time, stand on tiptoe.

Where to put?

Before starting work, it is important to immediately determine for what and how often the table will be used, where it will be placed. You can't do without a drawing. The answers to these questions will determine its dimensions, material and manufacturing procedure.

The best place to place the device can be considered that part of the room (garage or barn), where there is daylight. It is also important that there are electrical sockets near the workbench to connect power tools and a lamp. It is best if the light falls from the left or straight, then the working surface of the table will be illuminated during the day.

Design the dimensions of your work area.

Then the parameters of the future design are determined. Despite the existing standards regarding the size of the table, if you make a carpentry workbench with your own hands, the home master will proceed from expediency and the actual space available, so the tabletop will be such that tools and parts are freely placed here, without strict adherence to dimensions. The width is usually 50-60 cm; this size is considered optimal, as it allows you to freely reach the opposite edge of the countertop.

The typical vertical table size is in the range of 850-950 mm.

Another important parameter is the height of the workbench. Exist various ways its definitions, ranging from precise mathematical calculations to folk experience, which proposes to consider the distance from the extreme point of the arm bent at the elbow to the floor as the optimal indicator. An experienced craftsman can make it adjustable.

A perforated metal sheet is perfect as a wall for placing tools.

After determining the main parameters of the product, you can proceed with the assembly.

- First, the legs are fixed (four supports from a steel angle, which are also connected by angles and fixed by welding from above and below.). The result is a rectangular welded structure.

- After the frame is made, they begin to prepare the countertop. Boards cut to size are laid out on top of the frame and tightly fastened. The tabletop is connected to the frame with bolts. The working surface must be processed: planed and sanded. The bottom must be secured with crossbars or wooden blocks. They are screwed to each of the elements of the resulting shield.

After fixing it, you need to cover the cover with metal (it is better if it is galvanized). The metal sheet is fixed on the surface of the countertop with self-tapping screws. If burrs form, they must be cleaned.

The workpieces should be cut before the start of welding.

The main work on the manufacture of the workbench is completed at this point, but to make the structure more rigid and attach to the floor, metal corners can be welded from below. Optionally, it can be equipped with drawers, shelves for tools.

We reinforce all welded joints with a corner or a steel strip.

From necessary equipment on the workbench, you must definitely find a place for a vice. They are hung on the front side of the countertop and are used to fasten products. If there are often large parts in the work, there is a need to install several vices of different sizes.

The key is to reinforce all 90° connections.

Under the workbench, you can mount shelves where you can place various fixtures, the right tool or fold the processed parts.

Be sure to impregnate the tree with an antiseptic and fire impregnation.

Carefully made with your own hands, the carpentry workbench will become a convenient tool for the work of a home craftsman.

This design is close to the ideal of a do-it-yourself garage workbench.

VIDEO: do-it-yourself workbench.

Creating a workbench with your own hands: 50 photo ideas

A comfortable workplace, well-equipped, with a solid carpentry workbench, can greatly facilitate the processing of wooden products. This makes it possible to speed up the production process and improve the quality of the final product.

If there is no time for manufacturing, you can purchase a ready-made workbench in the distribution network. In comparison with this option, hand-made desktop production has several advantages:

- opportunity to get a carpentry workbench right size and functionality;

- rational placement of work units and additional equipment;

- the purchase of a finished workbench will cost much more.

Design requirements

Depending on the intended work, the carpentry table must have the following characteristics:

- The mass and rigidity of the structure must be sufficient to ensure the integrity and stability of the desktop.

- The presence of devices for fixing and holding the workpieces (stops, screw clamps,).

- Possibility of ergonomic placement of additional equipment.

- The dimensions of the future carpentry workbench depend on the mass and dimensions of the workpieces that are supposed to be processed on it.

- The free space in the workshop should be taken into account. There are projects of compact workbenches that allow you to organize a workplace even on the balcony.

- The height of the table should be oriented to the physiological characteristics of the person who will work behind it.

- Additional devices should be placed taking into account the main working hand of the owner.

- Before starting the design of the workbench, you need to decide what it will be - portable or stationary.

The most suitable workbench dimensions for working with wood:

- tabletop length - 2 m;

- width - 70–100 cm;

- table height from the floor - 80–90 cm.

Types of carpentry workbenches

If there are no serious functional requirements for the workbench, a desk converted to professional needs can be used for small jobs.

mobile workbench

This type of carpentry desktop is relevant in case of a lack of free space in the workshop. Its length is no more than a meter, and its width is 60–80 cm, and its weight usually does not exceed 30 kg. It is convenient to use a portable mobile workbench for processing small workpieces, minor repairs of joinery, woodcarving. Due to its compact dimensions, the mobile machine can be placed in any room: in the garage, in the country house or on the balcony. For even greater compactness, a folding design is often used.

Scheme for the manufacture of a mobile workbench

Stationary workbench

A full-fledged working facility with reference to a specific place, without the possibility of mobile movement during operation. Designed for processing workpieces of any weight and length (within reasonable limits). This is a powerful, reliable device, made taking into account the characteristics of the workspace and the personal preferences of the master. Stationary machines are necessarily equipped with special clamps for fixing workpieces. They provide a place for fixing the tool and installing additional stops.

Composite carpentry workbench

Thanks to collapsible design on bolted connections, individual modules of the machine can be easily replaced during operation. The main drawback of this device is the complexity in manufacturing (compared to other models), which is largely offset by its variability in the process of use.

Selecting a project and drawing up a diagram

When drawing up a project, the main parameters that need to be taken into account are height, configuration and functional equipment.

Height. For comfortable long-term work, the height of the workbench should not be more than 90 cm. When determining this parameter, first of all, you should take into account your height (if the workbench is made for yourself). And also important is the type of carpentry work that is supposed to be performed most often, and those that require the most convenient conditions for their high-quality performance.

Configuration. If there are no restrictions on the working space, the optimal width is 80 cm, length is 2 m. When configuring the workbench, you need to take into account the presence of shelves, compartments, doors, drawers, their number and size.

Functional equipment. To hold workpieces, the carpenter's workbench must be equipped with two clamps. The front clamp is located on the left, the rear clamp is on the right end of the workbench. This clamp layout is right-handed. If the master has the main working hand left, the clamps are mirrored relative to the above option.

It is necessary to provide places for fixing electrical and hand tool, technological holes for stops and limiters. Lighting and outlets are best located on nearby walls and objects.

Necessary materials

When selecting material for each workbench node, it is necessary to take into account the functional features and loads to which it will be subjected.

In order for the workbench not to turn out to be too massive, light softwood is preferred as the material for making the frame:

- Pine;

- alder;

- Linden.

Hardwood, as well as plywood of various thicknesses, is used to make countertops.

The frame for the workbench can be welded from metal square pipe or a corner of a suitable section, but most joiners prefer wood structures.

Making a simple table

As an example, the manufacture of a carpentry workbench with a worktop 2 m long, 80 cm wide and 80 cm high is taken. For more rational use time, you first need to glue the countertop. While it is glued, you can prepare the components of the frame and its subsequent assembly.

During the manufacturing process you will need:

- miter circular saw;

- drill;

- electric jigsaw;

- clamps.

Table top assembly

Type-setting (glued) shield made of hardwood (ash, oak, beech, hornbeam). The recommended table top thickness is 60 mm. It is most rational to use a planed beam with a section of 60x40 mm for its manufacture. After preparing the length of the timber, it must be glued together into a shield of the required width. To get a shield 80 cm wide, you need to prepare 20 bars 60x40 mm.

For high-quality gluing, the following factors must be taken into account:

- The beam is strictly rectangular in cross section(not a rhombus or a parallelepiped).

- The shield must be clamped with special clamps that are capable of providing sufficient clamping force.

- Gluing is carried out on a flat plane, while deformation during compression must be excluded.

You can do without all of the above and glue the shield by successively compressing the bars together with self-tapping screws or even nails. But in this case, about no flat surface countertops are out of the question.

Plywood tabletop. Several sheets of plywood are glued together along the plane. The number of sheets to be glued depends on their thickness and on the planned thickness of the countertop. For high-quality gluing of plywood, a flat plane is required. The quality of the finished countertop depends on how even this plane is.

There are two options for gluing plywood at home:

- With boards and clamps. Glue is applied to the plywood and compressed with clamps. For uniform compression, boards are placed under the clamps.

- With planks and weights. Plywood pre-lubricated with glue is placed on a flat plane, boards are placed on top and pressed with a load.

Support manufacturing

The supporting legs of the desktop are made of timber with a section of 100x100 mm. They look quite massive, but this is necessary to ensure the rigidity of the structure. The transverse frame parts are made of the same wood as the legs. For this, a beam with a section of 60x60 mm is enough.

In order to avoid the deformations that large-section solid wood parts are subject to, it is better to use for the manufacture of supports. It can be glued together from two or three blanks of a smaller section. For example, to make a beam with a section of 100x100 mm, you need to glue together three boards with a section of 105x35 mm along the plane. After gluing, you will get a blank 105x105 mm, where 5 mm is a margin for finishing.

To assemble the frame, spiked joints or dowels are used. This assembly option requires the presence of special equipment. Otherwise, the process will be unreasonably long. A simpler option is to use metal fasteners and fittings (bolts, screws, corners, self-tapping screws).

Frame size:

- length - 180 cm;

- width - 70 cm;

- height - 74 cm.

The height is given taking into account the thickness of the tabletop (60 mm). The length and width of the frame ensures the presence of overhangs of the table top (10 cm per side from the ends, 5 cm per side in front and behind).

When assembling, the following blanks should be obtained:

- Racks (legs) - 100x100 mm, 74 cm long.

- Cross bars - 60x60x1600 mm (4 pcs.) And 60x60x500 mm (4 pcs.).

If you use spiked joints, then the length of the workpiece must be added to the length of the spike (recommended 60 mm), multiplied by 2.

Frame and table assembly

Before assembling, to the bottom of the tabletop along the edges, you need to attach transverse boards with a section of 100x60x800 mm and longitudinal 50x60x1800 mm. Cross boards are needed to prevent deformation of the countertop during operation. Longitudinal - for the subsequent equipment of the carpentry workbench with clamps.

To securely fix the longitudinal and transverse boards, glue should be used. If there is no confidence in the quality of the adhesive, they can be additionally fixed with self-tapping screws or other metal fasteners.

If all dimensions are taken into account correctly, then the frame of the workbench will become clearly between the transverse and longitudinal boards from the bottom of the table top. The entire structure should be fastened with bolts, through the transverse boards of the table top and support pillars (legs). To prevent the bolt heads from interfering, countersunk holes must be drilled under them.

Folding design

It is advisable to use a folding workbench when the amount of working space is limited and the mobility of moving the desktop during operation is necessary. In most cases, a carpentry portable workbench is equipped with a removable top and a folding frame.

The tabletop can be hinged against the wall, and the legs can be folded under it. When using this design, the length of the legs should be calculated in such a way that they do not interfere with each other when folded. That is, their length should be less than half the distance between them.

Similar carpentry workbenches are designed for processing small parts. Therefore, the structural elements of these tables are not made as massive as on stationary ones. For the manufacture of support posts, a beam of 100x40 mm, transverse 60x40 is sufficient.

Any board material (OSB, chipboard, plywood) can be used as a countertop material. If the thickness of the board material is not enough, the tabletop can be reinforced with a frame of 30x50 timber (the cross section of the timber is determined by the planned rigidity of the tabletop).

Assembly of a folding joiner's workbench is made on bolts. In order for the table to be quickly disassembled, it is advisable to use special wing nuts instead of ordinary nuts.

The general principle of the development of material processing technology from prehistoric times to the present day is how to make details on inaccurate equipment for more accuracy. And it all started with a workbench, its prototypes are found during excavations of Stone Age settlements. It is quite possible to build a workbench, and a full-fledged one, with your own hands, and this will not only save a significant amount, but also simplify, facilitate work and improve its result.

Three mistakes

Amateurs, sometimes, judging by their designs, very experienced, knowledgeable and diligent, sometimes make workbenches for themselves, on which, figuratively speaking, a tank can be smashed with a sledgehammer. They take a lot of time and labor, and hardly less money than a good branded amateur workbench. Repetition in the design for own use of industrial prototypes designed for intensive work in 3 shifts and a static load of more than a ton, with a service life of 20 years is one of common mistakes development of workbenches of their own design.

The second is the neglect of vibrations. Not a clearly felt “play” or “recoil”, but a small tremor that significantly complicates the work and reduces its quality. Vibrations are especially strong in workbenches on a metal bed.

Third - repeat carpentry or locksmith workbenches; perhaps with some tweaks to your liking. Meanwhile, there are many designs of workbenches for home / amateur work of a different nature. There are workbenches that are more or less specialized or, on the contrary, universal, temporary from improvised materials, etc.

In this article we will figure out how to make a workbench taking into account these errors, firstly, simpler and cheaper according to the range of needs and / or hobbies of the craftsman. Secondly, how to make a general-purpose workbench or a universal workbench for special conditions of use - in a cramped garage, under carpentry at a construction site from improvised trash, home for fine precision work, for children.

About universal workbenches

Among the branded products, sometimes very expensive, you can find "universal" workbenches in the form of a carpenter's with a lid without a tray, a complete bench vise on a wooden cushion, and a clamp for installing them, like the one in the photo:

“Universal” prefabricated workbench

This is the wrong decision, not only because the wooden countertop deteriorates from carpentry. The main thing that is bad here is the technological fluids used in metal processing - oil, kerosene, etc. The wood impregnated with them becomes much more combustible. Self-ignition is also possible; remember, it is strictly forbidden to accumulate oiled rags in production. The approach to designing the countertop (board, cover) of a universal workbench needs a different one based on what kind of work it is mainly used for - thin or rough, see below.

work bench

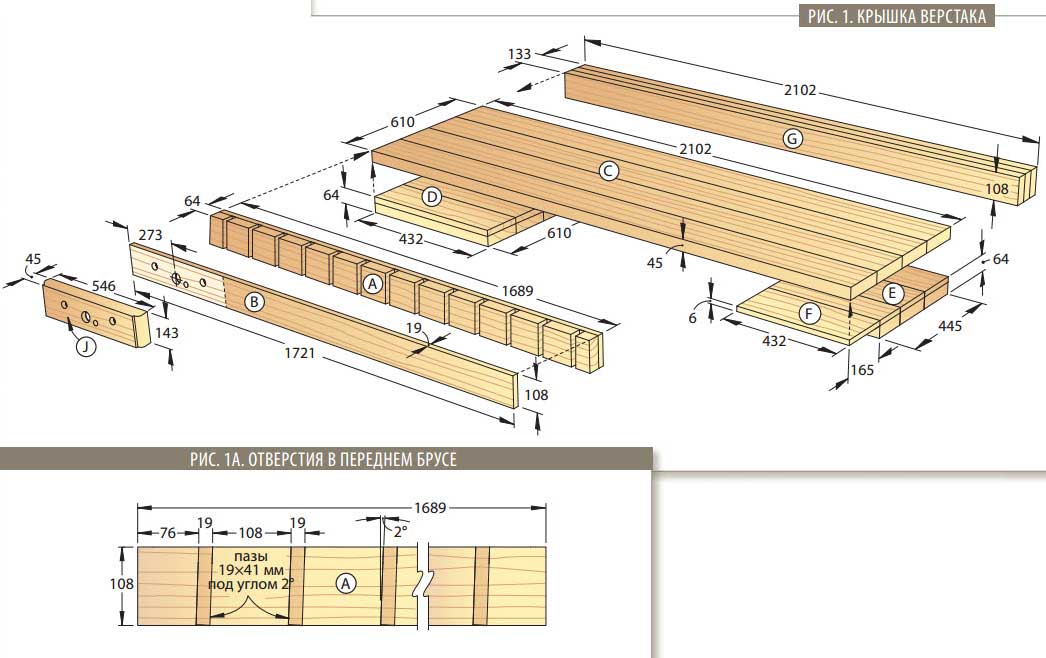

In the West, amateur / home workbenches with a type-setting worktop framed by a side are widespread. Drawings of such a "working bench" are given in fig. Under the locksmith, the lid is covered with a sheet of steel 1.5-2 mm thick and a vice is placed on the pillow.

The workbench dampens vibrations well; You can make it from pine or spruce. But the design is complicated, it is inconvenient to work with lengthy materials and furniture on such a workbench. Therefore, we will first look at how to make the most common carpentry workbench, then garage and metalwork. Next, we will try to combine them into a universal workbench and see what we can come up with on this basis for special needs.

The composition of the workbench

The workbench of "our" type (conditionally, since it is impossible to establish its origin exactly) consists of:

- Underwork (in carpentry workbenches), or bed (in metalwork), ensuring the stability of the entire unit and the ergonomics of the workplace.

- Covers, box-shaped or in the form of a tray, giving the work area the necessary rigidity.

- Shelves; possibly with a tray, nests, and stops on which work operations are performed.

- The apron on which the tool is hung. The apron is not a mandatory accessory of the workbench, it can hang on the wall or be replaced by a pedestal, rack, etc.

Note: workbench height approx. 900 mm. The length and width are selected according to the place of installation and the type of work within 1200-2500 and 350-1000 mm, respectively.

A lid with a shelf is most often made at the same time, one-piece, and is simply called a lid, benchtop or tabletop. To dampen vibrations, the shelf is always made on the basis (bed, substrate) of wood. In a locksmith's workbench, the bed is covered with a steel sheet from 2 mm thick and can be made of coniferous wood. Its overall strength is sufficient, and the steel tire protects the tree from local damage and ingress of technical fluids. In a carpenter's workbench, a bed made of high-quality (without knots, strands, and other defects) solid small-layer wood (oak, beech, hornbeam, elm, walnut) serves at the same time as a shelf; -layer construction, see below.

The traditional construction of the bench, on the contrary, is collapsible from the same wood as the joiner's shelf. This comes from the master covens of the past, who transported their equipment from customer to customer on a cart. It is from the bed / underbench that you should start developing your workbench no worse, but simpler than traditional ones.

Bed: metal or wood?

A stationary wooden workbench has advantages over that on a steel frame, not only in lower cost and labor intensity. Wood, firstly, is not plastic. Workbench on wooden base can be broken, but if the wood is used seasoned and impregnated, it will never sag. Secondly, the tree perfectly dampens vibrations. The foundations of your buildings are not reinforced vibration-absorbing ones, like workshops at a factory, are they? And the overall strength and stability of the bed of a home workbench will be fully provided by coniferous commercial wood of ordinary quality.

The design of the wooden frame of the workbench made of boards 120x40 is shown on the left in fig. Permissible static load - 150 kgf; dynamic vertically down for 1 s - 600 kgf. Corner posts (legs) are assembled on self-tapping screws 6x70 in a zigzag (snake) with an indent from the edge of 30 mm and a step of 100-120 mm. Double-sided fastening; snakes on both sides of the package are mirrored. Intermediate support beams are fastened with steel corners on self-tapping screws; edge - with pairs of self-tapping screws at the spikes of the racks and, outside, with corners.

If a beam of 150x50 or (180…200)x60 is available, the design can be simplified, as shown in the center in fig. Load bearing capacity will rise to 200/750 kgf. And from a bar 150x150, 150x75 and (180 ... 200) x60, you can build a frame that can carry 450 kgf in statics and 1200 in dynamics, on the right in Fig.

Note: any of these beds is suitable for both carpentry and locksmith workbenches. A box-shaped cover is placed on it under the carpentry (see below), and under the locksmith a tray from a 60x60x4 corner with welded 4 mm strips above the intermediate beams. A wooden pillow is placed in the tray and covered with steel, also see below.

If there is no welding

An all-wood workbench, without the need for welding to manufacture it, can be made according to the scheme on the trail. rice. The “chip” here is in the tabletop, glued from a 75x50 bar and fastened with ties. If the beam is oak, then the permissible load is 400/1300 kgf. Corner posts - timber 150x150; the rest is timber 150x75.

Metal

It happens the other way around: metal is more accessible than wood, and there is welding. Then the workbench table for a load of 100/300 kgf can be assembled according to the drawing on the left in fig. Materials - corner 35x35x3 and 20x20x2. Drawers are galvanized. The disadvantage is that it is impossible to make an opening at the bottom for the legs, the structure will lose its ability to carry a dynamic load.

Under a load of 200/600, a more convenient metal workbench is suitable according to the scheme at the top right of a professional pipe 50x50 (corner posts), 30x30 (other vertical parts) and a corner 30x30x3. The plank cushion of both workbenches is laid only across (bottom right) from tongue-and-groove boards (120 ... 150) x40.

Shelf - steel 2 mm. The shelf is attached to the pillow with 4x (30 ... 35) self-tapping screws, a pair from each edge of each board, and along the extreme boards - with a step of (60 ... 70) mm. Only in this design, the workbench will show the specified load-bearing capacity.

These workbenches are already universal: they turn the lid under the carpentry wooden side up or adjust as described below. The locksmith's vise is mounted on a wooden cushion, but is not fastened with a clamp. A collet anchor under the M10-M14 bolt is driven into the vice cushion from below, and a through hole is drilled under it in the cover. A washer from 60x2 is placed under the bolt head. This solution is convenient because it is possible to use inexpensive non-rotating vise.

For carpentry

The lid of the carpentry workbench, in contrast to the metalwork, is tightly attached to the workbench and is box-shaped, for general rigidity. The best option fastenings for a non-separable workbench - steel corners and self-tapping screws. Podverstache can also be a steel bed from those described above.

How a traditional carpentry workbench is arranged is shown in pos. And rice; accessories to it in pos. B. The workbench (in this case, this is a separate device) is used to work with a long length. The emphasis in its groove is made from a wedged trimming of the board, see below. It is advisable to drill a longitudinal row of holes in the board and fasten it into the sockets with sunken cone-head bolts. The traditional construction of a carpentry underbench is shown in pos. G, but - see above.

The cover of the carpentry workbench can be made cheaper by making a 2-layer, pos. Q. Then high-quality hardwood boards will only be needed for a shelf. They lay it down, laying the boards with “peas” of annual layers alternately up and down, in order to avoid warping. The flooring of the shelf is first rallied with PVA glue or carpentry, tightly squeezing with a clamp or wrapping it with a cord; put on a pillow on the same glue. The skirt of the lid is assembled separately with glue and through spikes (insert at pos. B) and is attached to the pillow-shelf package with self-tapping screws.

Vice for carpentry

All-wood carpentry vices, front and chair, are now almost completely replaced by a vice with a metal screw clamp, pos. D; their device is shown in pos. E. Some remarks are needed here.

First, you need to put 2-3 steel washers under the head of the clamping screw, otherwise it will quickly eat through the pillow (4x4x1 cm piece of wood). Second - if the nut is not custom-made and not purchased shaped, then get at least for a while a set of taps for the thread used. In this case, do not try to use too thick a screw for evenness and smoothness of the clamp; M12-M16 is enough.

The nut of a home-made clamping pair is welded onto a base with a diameter of 60 mm or more, square, from 70x70 mm. It is not necessary to sink it into the clamp pad, so it is less likely that the nut will be torn off when clamping. But the thread will ugly lead away from welding, you can’t drive it away with a bolt. The thread of the welded nut will need to be tapped according to the full scheme, as when cutting: the first tap - the second - the third (if included in the kit).

Note: the nut welded on the base must be allowed to rest for at least 2 hours before the thread passes, so that the residual deformations “subside”.

Vice and carpentry for a locksmith

The vise on the locksmith's workbench is installed in the corner (see sidebar in the figure), so that as much as possible of the dynamic loads during metal processing falls vertically on the corner post. Location cross beams and intermediate uprights It is desirable to make a workbench with a stationary vise a little asymmetrical, placing them at smaller intervals towards the corner with a vise. The installation of the vice is also carried out starting from the corner:

- A collet anchor is driven into the wooden corner post under the mounting bolt, and a high nut or threaded sleeve is welded into the metal post (attachment point 1 at the bottom left in the figure);

- If the fastener is welded, thread with taps, as in a homemade carpenter's vice nut, see above;

- Put a vice temporarily on 1 bolt and mark holes for fixing points 2, 3 and 4 in place;

- The vise is removed and through holes 2, 3 and 4 are drilled;

- Put a vise on the bolts 1, 2 and 3;

- For fastening to bolt 4, a jib U is placed under the cover (table top) from a wooden beam from 60x60 or a professional pipe from 40x40. It is not necessary to fix the jib, but it should rest from under the bottom against the upper frame (strap) of the bed, but not against the table top!

- Attach the vise finally to the bolt 4.

Note: stationary power tools are also fixed in the same way, for example. emery.

Under the carpentry

A locksmith's workbench can also be adapted for carpentry work if you drill 2-4 pairs of holes in the tabletop for fixing the carpentry stop (on the right and in the center in the figure). In this case, round bosses are screwed to the bottom surface of the stop with self-tapping screws; plugs fit well plastic bottles, they withstand tight landings many times.

Garage workbench

A workbench in the garage cannot be made optimal in terms of ergonomics of the width of the workplace - the dimensions of a standard box 4x7 m with a car standing in it do not allow. For a long time already, through trial and error, the width of the garage workbench was determined at 510 mm: it is quite convenient to turn between it and the hood, and you can more or less work. A narrow workbench under a heavy load (for example, a motor taken out for bulkhead) is unstable, so it is made attached to the wall. Often - angular, this increases stability, but any wall-mounted workbench "responds" stronger than a workbench-table of the same design

The scheme of the device of one section of the garage workbench is given in fig. In this design, an ingenious method of additional damping of vibrations is used: cells of the frames of the cover and the lower shelf of the edge farthest from the corner of different sizes. The accuracy of the installation of the crossbars is +/- 1 cm. For the same purpose, the cover and the lower shelf are made of chipboard 32 mm thick and covered with linoleum instead of steel. For garage work, its durability is sufficient; replaced without difficulty.

Fastening to the walls - self-tapping screws from 8 mm or bolts from M8 with a pitch of 250-350 mm. Deepening into a stone wall 70-80 mm; in wooden 120-130 mm. Propylene dowels are placed under the screws in the stone wall; for bolts - collet anchors.

More for the garage

Another version of the garage workbench is already on the wall, and on the wall, on the left in fig. It can only be mounted on stone walls. Bench board folding 2-layer; each layer of plywood 10-12mm. Opening under the machine with a stepped inner edge. In this case, a “milling cutter” means a mini-drilling machine with a movable rotary table and a workpiece clamp. The design is convenient in that the chips fall immediately onto the floor.

If your car is something like a Daewoo or Chery with a 3-cylinder engine, and the garage is very small, then you can put a folding mini workbench with a lifting tabletop in it, on the right in the figure; it will also fit into the house for fine work (electronics, precision mechanics). The tabletop is suspended on a piano hinge, the legs are on card hinges. For folding, the legs are tucked under the tabletop (it would be useful to tie them with a leg), and the tabletop is lowered.

Note: for a cramped garage with an ordinary city car, a folding workbench-box may be optimal, see the video below.

Video: folding workbench box

Home station wagon

At home, they are engaged in smaller, but painstaking technical creativity: soldering, modeling, watchmaking, artistic sawing out of plywood, etc. For fine fine work, a universal workbench is suitable, the drawings of which and its accessories are given in fig. The resistance of the work surface and its vibration absorption in this case are not as important as evenness, smoothness and some adhesion (“stickiness” of parts), so the table top is covered with linoleum. Locksmith vices for this workbench need small, with screw clamping.

More about plywood

In fact, it is undesirable to work with metal “roughly” on plywood, because. she calls back well. If, however, the pillow of the board of the locksmith's workbench is still made of plywood, then a frame (frame) must also be glued to its bottom on the PVA, also made of plywood, see fig. Then it is desirable to cover the upper (working side) first with unlined linoleum, and then lay steel on it.

To the rising shift

Another case where making a workbench out of plywood is justified is a student's workbench for a child. Pedagogical considerations play a role here: let him learn to feel the material and not to beat for nothing, but to work carefully. For the same purpose, the masters of the past deliberately gave students a bad instrument.

Workbenches in the country

When country house or other light wooden structure is still being built, there is no time for bench wisdom, you need at least something on which simple carpentry work can be done. For such a case, hastily you can put together a carpentry workbench for giving from improvised materials, on the left in fig. The design is remarkable in that it clearly and fully embodies the principle: we do good things with bad equipment.

For subsequent work on the arrangement of the dacha, a mini-workbench is useful, on the right in fig. With a minimum consumption of material and an extremely simple design, it is stable enough for ordinary carpentry work in all respects, because. the middle of the workbench is supported by a pair of struts. If you put them on bolts, the workbench will turn out to be collapsible and stand in the pantry from weekend to weekend. For disassembly, after releasing the struts, the spacer is removed with them, and the legs are tucked under the board. Finally, for a summer residence, inhabited permanently or all summer, with a master owner, by the way, you will have a more complex, but fully functional folding workbench, see the video below.

For a zealous owner, a desktop is an indispensable attribute of a garage, barn or extension to the house. Of course, a carpentry workbench can be purchased. But if this product well-known brand, it is quite expensive. In addition, it is not known whether it will fully meet all the requests of the master. Cheap tables will not last long - definitely.

The most rational solution, if you really want to have the most convenient and versatile carpentry workbench, is to make it yourself. Having dealt with optimal dimensions, drawings, features of the selection of materials and a number of other issues, it will become clear that there is nothing difficult in this for any man.

Selecting a workbench project

You need to start with this. Any desktop is made for some specific purposes and premises. Joiner's workbench - the name is generalized. One is needed only for woodworking on personal plot(e.g. during construction or overhaul), the other is going for everyday work with small details, and from different materials. Depending on the specifics of use and the place of installation, its design features, dimensions, and drawing are determined.

Option A - portable workbench (mobile). Such a desktop is most often assembled with your own hands for small rooms (an extension, a garage), with a complex layout, and its main purpose is to perform small work with small parts. The relatively low weight of the structure makes it easy to move it, if necessary, to another segment. As a rule, the maximum that such a workbench can be equipped with is a medium-sized vice and e / emery. This will allow the carpentry table to be partially used for small plumbing work.

For domestic purposes, a table according to option A is best suited for a home master. It is called mobile only conditionally, only because of its relatively low weight. If a specific place is allocated for him in a barn or garage, nothing prevents the owner from fixing his legs on the floor (fill with concrete, “fasten” with large self-tapping screws, and so on). With your own hands, whatever.

Drafting a carpentry workbench

If the workbench is going to domestic use, then there are recommended linear parameters (in cm) that you can focus on. But this is not an axiom, so the master himself is free to change anything, at his own discretion.

- Length - at least 180.

- Working surface width – 90±10.

- Workbench height - 80 ± 10 (taking into account the thickness of the tabletop). Deciding on this parameter, you need to focus on your own growth. It is unlikely that working with a tree will be effective and will bring satisfaction if you have to constantly slouch or, on the contrary, rise “on tiptoe”.

What to consider:

- The number and type of compartments in the cabinet table. It can be open boxes, drawers or drawers with doors, shelves. Another thing is whether the master needs them?

- To make it more convenient to work with samples of different lengths, it is worth drilling several “nests” in the tabletop to install limiters.

- To fix the workpieces, it is desirable to have a couple of clamping devices (clamps or screw vices) on the workbench. The optimal width of their "sponges" is 170 ± 5 mm.

- Desktop location. Depending on the level of illumination, the number of lamps fixed on the workbench (and above it) is determined. But at least a couple of pieces, on the edges of the tabletop, are necessary for “spot” lighting.

If the owner is left-handed, then this should be foreseen. All standard drawings posted on the Internet are designed for craftsmen whose "working" hand is right. Therefore, you will have to place additional / equipment on the table according to the “mirror” principle.

Workbench drawing example

Selection of materials

The bar is planed. He will go to the frame (frame) of the workbench. The section is selected in accordance with the dimensions of the structure. For a large table - at least 100 x 100. If it is compact, for universal use, you can limit yourself to blanks of 100 x 70 (50). They are also perfect for various jumpers. Board. For a countertop, its minimum thickness is 50. Here you need to think about how to use the workbench more rationally. For example, to make it truly universal, one part of it can be specially adapted to perform plumbing work, that is, with metals. In this case, it is advisable to take a more massive board (for example, "sixty") and upholster a small segment of the tabletop with sheet iron. This is just one of the ideas that you can implement with your own hands when determining the design features of the workbench.

The desktop is not installed in the living quarters. And in the workshop there will definitely be differences in both temperature and humidity. That's why for the manufacture of a workbench, wood is recommended - hornbeam, beech, oak. The only disadvantage of this solution is the high cost of materials. You can choose a cheaper option - maple, larch. These rocks are characterized by sufficient hardness. Although for the countertop of a home-made workbench, if it is not planned to carry out any “impact” work on it, plate samples (chipboard, OSV) are sometimes taken. In principle, any good owner can easily determine what suits him best.

Too porous wood should not be used. Even its high-quality treatment with antiseptics, oils will only increase the water-repellent properties, but will not add strength to the tree.

fasteners

- Bolts. There are no particular difficulties with them. They should be of such length that a washer, grover and nut can be placed on the back side. More difficult with other types of fasteners.

- Nails. How appropriate it is to use them when assembling a workbench with your own hands (and such recommendations are quite common), everyone will determine for themselves. But a number of remarks are worth making.

- Firstly, a nail, especially a large one, easily splits wood, especially if it is overdried.

- Secondly, it is unlikely that it will be possible to drive it strictly vertically, given the length of the leg and the strength of the wood from which the workbench is made.

- Thirdly, the difficulty with dismantling. For example, if it is necessary to repair the desktop with the replacement of a component. It is not always possible to pull out a tightly clogged “powerful” nail.

- Self-tapping screws. For a small workbench - the best choice. The most "problem" areas can be additionally reinforced with metal strips, corners, plates. The main thing is to correctly choose the length of the leg of the fastener. There is a rule according to which it should exceed the thickness of the fastened part by 3 times, at least. Otherwise, the strength of the connection is questionable.

Assembly instructions for a carpentry workbench

In the process of making a desktop with his own hands, the master must constantly, at every stage, control the angles and levels. The slightest distortion even in one place - and everything will have to start over.

Manufacturing of workbench parts

- This is easy to do according to the dimensions in the drawing.

- Each sample is carefully polished.

- Depending on the type of wood, an impregnating composition is selected and parts are processed to protect them from destruction by rot and wood-boring insects.

- Drying. This is worth focusing on. It is impossible to initiate this process with the help of artificial heating, otherwise the workpieces will begin to deform - bend, twist. Moisture should evaporate only naturally - in a room with room temperature and good ventilation.

Base Frame Assembly (Workbench Base)

Partially about the features of fastening has already been said - self-tapping screws + reinforcement elements. But still, the main method of fixation is a tenon-groove connection with a fit on carpentry glue. But the fasteners only add strength to the entire structure of the workbench. But this is practiced only for massive tables that are not planned to be disassembled in the future (stationary options).

Here you should consider the degree of maintainability of the workbench. If he is in a room with good conditions, then it is unlikely that the wood will quickly begin to rot. In such cases, adhesive joints are fully justified. For desktops that are located in cold sheds, unheated boxes, and even more so in the open, “landing” on glue is undesirable. Partial repairs cannot be done, and the frame will have to be reassembled.

Additional reliability of the design can be ensured by installing various jumpers - diagonal, horizontal. All this is thought out even at the stage of drawing up the drawing, although it is possible to make “refinement” during the installation process.

table top

This is the most loaded part of the workbench, and it is advisable to make it removable. In this case, it is easy (in case of significant damage) to replace 1 - 2 boards.

- The width of the countertop is selected so that its surface extends somewhat beyond the perimeter of the frame. Otherwise, it will be inconvenient to work on such a workbench. Yes, and fixing the removable vise will no longer work.

- The side parts of the boards are carefully polished. If you do not achieve an accurate fit of the samples, then you cannot avoid the appearance of cracks.

- The blanks are stacked face down (on a flat base) and fastened with bars. They are placed perpendicular to the center lines of the boards, and the thickness of the latter allows them to be pulled with thick self-tapping screws. In extreme cases, it is easy to drill deep chamfers at individual points.

- To make the tabletop removable, it is fixed on the frame using metal corners.

- After its manufacture, additional grinding of the front part is performed. To extend the service life, it is advisable to treat the working surface with impregnating agents (wood oil, drying oil).

Workbench equipment

At what stage and what exactly needs to be done is decided depending on the modification of the desktop and the selected drawing. For example, the same vise. They can be purchased, which are easy to attach to the edge of the workbench. People with experience in carpentry make clamping devices on their own.

In principle, a man who is “friends” with the simplest tool should not have any difficulties when assembling a carpentry workbench. The only recommendation is that before you start drawing up a drawing, you should carefully review all the photos of desktops available on the Internet.

Even if they do not have sizes, it is not difficult to determine them. But with a high degree of probability it can be argued that there will be new, interesting ideas. After all, the workbench can also be folding, which is very convenient in a small box or barn. Yes, and having familiarized with the complete set of the table, design features different models, you can come up with something of your own, original. After all, the beauty of assembling with your own hands is in the absence of any canons. Only creativity + knowledge of the issue.

A home master must have a comfortable place, this is a guarantee not only of convenience and speed of work, but also of safety. High-quality European-made workbenches cost as much as industrial equipment, Chinese and handicraft assembly - do not differ in reliability. However, you can make a good workbench with your own hands, because, in fact, this is a table equipped with various fixtures, stops and a place to store tools.

Workbench project

The height of the workbench depends on the height of its owner, it should be comfortable while standing, without stooping to perform basic operations. For an average height, this is usually 70-90 cm. The configuration of the workbench and the necessary fasteners and fixtures depend on what operations are most often performed on it, but provide for several stops and a pair of screw vices or clamps (). You also need to take into account which hand the owner of the workbench works with.

Workbench scheme - the first option

Workbench scheme - the first option

The width and length of the workbench depend on the area of the workshop, it is convenient if the length of the workbench is at least 2 meters, and the width is 80-100 cm. It is convenient if boxes or cabinets for storing tools and consumables are mounted under the workbench.

When designing a workbench, you need to consider whether it will be permanently installed in the workshop or constantly assembled and disassembled. In the second case, it would be reasonable to lighten the structure due to a material of smaller thickness. In a collapsible workbench, you can make an unscrewing tabletop, or you can provide for folding legs.

It is better to have a workbench by the window, additional local lighting is also required. Directly next to the workbench, you need to provide several electrical sockets for equipment. All wires near the working area must be enclosed in a box or corrugated pipe.

Selection of materials

The optimal material for the workbench is planed timber, from which the frame frame and legs will be made. For legs, you can take it with a size of 100 * 70 mm, and for jumpers - 100 * 50 mm. The tabletop can be made from flat boards 5 cm thick. It can also be made from a single piece of fabric, for example, an old blank door or laminated chipboard with a fairly durable coating. For a workbench, it is better to choose hardwoods, preferably beech, oak or maple. Thicker timbers and boards will make the workbench heavier and more stable, and it will be more comfortable to work on it.

Fasteners for the manufacture of a workbench are selected taking into account whether it will be prefabricated or collapsible. Self-tapping screws, nails and nuts with bolts will come in handy.

Before building a workbench, you need to pick up a vice. It is convenient if there are 2 of them - on the right side and on the left in front. In the first, you can fix long boards, and in the second, you can clamp short parts. The most versatile jaw width is 175 mm.

Scheme of the second version of the workbench

Scheme of the second version of the workbench

We build a workbench. Base

The manufacture of the workbench takes place in 2 stages: assembly of the base and installation. At each stage and during each operation, you need to control the size of the parts and the evenness of their installation using a level.

The base is a frame of bars fastened in such a way that the structure is as rigid as possible. To do this, a horizontal jumper is placed between the legs of the workbench, and in the middle, along the length, a drawstring is provided. Lintels and drawers are placed 40-50 cm from the floor, then shelves for storing tools can be installed on them. The bars for the base are combined with the help of a tenon-groove connection, gluing it. In places where this is not possible, self-tapping screws are used. If it is assumed that the workbench will be disassembled, then the parts of the support frame can be connected using metal corners. Usually, grooves and spikes are first prepared, according to the drawing, and then the entire structure is assembled at once, gluing the joints with wood glue and fixing them with clamps.

A good option for a stationary workbench, if one or more parts of the support frame can be screwed to the wall, then the construction will be even more reliable. Strength can be increased by using diagonal jumpers or wedge-shaped inserts between the legs and the upper part of the frame from the same beam, which are fastened with self-tapping screws. The narrow ends of the upper part of the frame must also be connected with a jumper.

Table top and useful accessories

If the countertop is constructed from separate boards, then they need to be properly driven to each other so that debris does not get into the cracks. The size of the countertop should be a few centimeters larger than the base, so that it is convenient to work and clean it. The boards are nailed or screwed to 3 bars located across the boards on the back of the table top. At the base, you need to provide grooves for these bars.

The board top is carefully sanded several times and coated with a protective solution, preferably oil or drying oil, to avoid injury from chips during further work. The tabletop is screwed to the base with metal corners.

A vise is attached to the finished tabletop, under them it is necessary to provide a recess in the end of the tabletop so that the vertical plate forms one plane with it. The underside of the workbench will also require a plywood gasket. The jaws of the vise should be flush with the table top. Applying a vise, mark the place for the holes and fasten them with bolts and nuts (M12 will do). The holes for the bolt heads must be pre-milled so that they completely sink into them. The vise should not be located in the very corner, so as not to disrupt it under heavy load.

In addition to the vise on the workbench, it is necessary to provide stops. You can fix the finished ones by drilling a hole of the desired diameter in the countertop, or make them yourself. It is not worth using bolts or round dowels instead of stops, since the bolts can damage the workpieces with their heads, and the dowels do not fix the parts well enough.

It is easier to make rectangular stops, or pegs, which are both height-adjustable for different parts and securely fix them. Under them, you need to make holes in the countertop or build it up with the help of bars of suitable thickness, screwed to its edge, and closed with a bar on the other side. The nests should be located at a distance of half from each other from the vise stroke so that any workpiece can be fixed.

The pegs themselves are sawn from hardwood, you can make them with a “spring” that is screwed to the base, or you can just make them rectangular. Rectangular stops can be slightly expanded upwards, then they will be fixed in the sockets more reliably.

Building a carpentry workbench with your own hands is not an easy task, but then this workplace will be able to serve the owner for a long time, acquire useful parts and fixtures and adapt to the specific needs of each craftsman.