DIY pool from scrap materials. How to make a swimming pool at the dacha (57 photos): preparatory and installation work

On a hot summer day, it’s difficult to deny yourself the pleasure of cooling off in a cool pond. Not everyone has a country house on the banks of a river or lake, and building a permanent pool requires space, time, and material costs.

Is there an alternative to capital expensive construction? Fortunately, people's ingenuity did not ignore this issue. We have selected not just the most interesting and simple ideas, but also the most viable ones that can be realistically implemented on a summer cottage without special skills.

The presented structures are not designed for 10-year use; they do not comply with all swimming pool construction standards. But the authors set completely different goals: cheap, fast, seasonal. Nevertheless, certain rules must be followed during such construction, so first we will familiarize ourselves with the general recommendations.

Important points when planning and building a homemade pool

Regardless of the choice of material for the construction of a seasonal pool, we recommend paying attention to the following points:

- the place for the pool should be in direct sunlight, and not in the partial shade of the garden: the water will heat up faster and there will be less debris in the form of falling leaves and insects;

- the area must be leveled and compacted;

- the bottom and walls of a homemade bowl should not have sharp protrusions or a hard surface;

- you need to immediately think about how and where the water will be drained during regular replacement (especially if installing filters is not provided);

- the frame needs to be strengthened so that the structure does not fall apart under water pressure;

- when purchasing a waterproofing film (tarpaulin), take into account the size of the container with a margin of 50 cm around the entire perimeter.

When installing a budget pool, do not forget about landscaping the area around it. You can make an embankment of pebbles or river sand around the perimeter, decorate the approaches with decking boards, or simply knock down wooden flooring from old pallets. Also, for comfort, it is advisable to consider a towel rack.

Just dig a hole and cover it with film

The first stage is the most labor-intensive - digging a hole of suitable size and depth. When the pit is ready: the bottom is leveled and compacted, the walls are perpendicular to the bottom and do not crumble, proceed to the second stage - preparing the surfaces.

Cut cardboard boxes are laid on the bottom to make it soft to step on. The walls are covered with bags so that the film does not tear on uneven surfaces and plant roots.

At the third stage, the pit is covered with waterproofing film. The upper edge is pressed with stones, which additionally plays the role of decoration.

You can bury a bowl made of scrap materials, covered inside with film, into the soil. This will require a lot of effort, but it will be possible to increase the depth of the pool. Since the edges of the bowl protrude above the soil surface, the soil will not be washed into the water.

We are sure that you will like the idea of having a swimming pool. And by next season you won’t want to build temporary structures. The optimal solution would be to organize a pleasant vacation spot for many years to come. To build a private pool, it is best to contact professionals who will help at all stages of its construction. The company "POSEIDONSTROY" has already received many good reviews. They will be able to make a pool according to your wishes or offer standard projects for implementation.

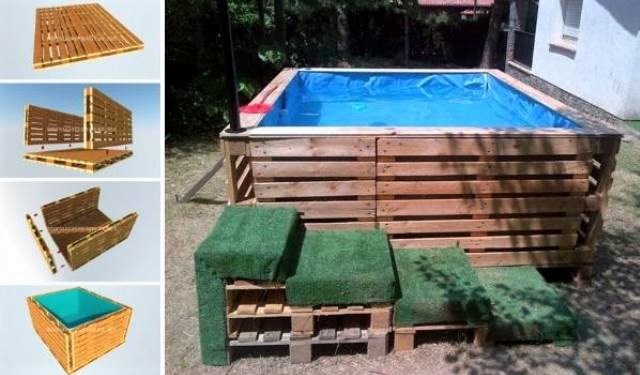

Frame pool made from pallets

To begin, choose a flat area and cover it with a thick tarpaulin (perhaps an old banner or canopy). Next, take 9 pallets and fasten them with screws and slats. Pallets are placed on edge, connected by a ring. When the round frame is ready, it is secured with tie straps for additional rigidity.

At the next stage, the inner surface of the “bowl” is covered with thick greenhouse film, and old towels, bedspreads or blankets are placed on top at the junction of the pallets and on the bottom. This is done to soften the surface so that while swimming it is comfortable to press against the stacks and walk along the bottom.

The final layer is a waterproofing film. If it is blue or blue, the water in the pool will always be bright. Some advise using black film to improve water heating. It is important that under the film there are no open sharp corners, protruding boards or rough surfaces on which the film will quickly tear.

The film is secured to the top edge of the pallets using a special adhesive tape. For decorative finishing of the outside of the pool, you can use reeds or bamboo. Narrow boards are nailed on top to hide the pallets.

The frame can also be made rectangular by connecting the pallets at right angles. The bottom can also be lined with pallets.

To create the most comfortable area, you can attach a lighting stand to the corner and make steps from pallets.

These pools are filled with tap water from a garden hose and drained manually or using a low-power pump. If chemicals were not used for disinfection, then vegetable beds and flower beds can be safely watered with water.

Pool made from old boxes

The frame of the pool can be made from old wooden or plastic boxes. They make up a rectangular box, fasten each one together and additionally wrap it around the perimeter with plastic tape.

The structure is assembled on a tarpaulin. The inside of the box is covered with a thick waterproofing film, pressing the top edge with wooden boards.

A pond made of hay - simple and cool

Looking for available materials for the construction of a swimming pond in the dacha sector, enthusiasts turned their attention to hay, which is an indispensable attribute of agricultural land.

It is spread out on a prepared area, and sides are built from rectangular compressed bales. Further, everything is according to the already shown scheme: a thick film is covered in the resulting bowl, the structure is tightened with belts. To protect the waterproofing film from damage, cardboard or a thick tarpaulin can be placed on the hay as the first layer.

Pool on a metal frame

For those who are familiar with welding, it will not be difficult to make a simple pool with your own hands from metal.

Each wall is made separately from a profile pipe and galvanized sheet. The structure can be assembled by welding or made dismountable with bolts.

An insert made of waterproofing film is installed inside, which, if desired, can be made to order according to the dimensions of the resulting structure. You can decorate such a pool using flooring from pallets, and also make a cover.

To increase ease of use, it is recommended to install a pump with a filter and use disinfectants for regular use. Thanks to this, your pool will not turn into a muddy swamp in a few days, the water from which will need to be completely pumped out and replaced with new water on a regular basis.

Mini-pool made from a large tire

Our selection will be completed by a very simple idea for making a pond from a large diameter tire from heavy special equipment.

To expand the future pool, the first step is to trim the sidewalls of the tire. The resulting workpiece is installed on a previously prepared concrete platform and filled with concrete. Thus, the tire and concrete form a bowl, which, after the concrete has dried inside, must be painted with a special paint.

As a result, you will get, albeit small, but not requiring much effort in maintenance and a very cozy pond that will help you cool off on hot days.

A swimming pool located in the courtyard of a country house or cottage is associated with luxurious living. This is true, because construction work and materials require significant financial investments. What to do if there is a great desire to have a pool in the yard, but there is not enough money? In this case, having shown ingenuity and creativity, you can create a swimming place in the yard using scrap materials with your own hands.

Tire pool: advantages and disadvantages, characteristics

As a building material for constructing a pool, you can use an old tire from a tractor, combine or large truck.

Its width and diameter are quite suitable for these purposes. Finding this material will not be difficult if you go to car repair shops, where they will sell you an old tire for a small amount. With its help, you can build a compact pool without spending a lot of time and effort. You just have to wait until the concrete base for this container hardens. Using tires as a material for building a pool has its pros and cons. The positive points include the following:

- the width of the tire is convenient because you will not need to look for materials to build the walls of the pool;

- the round and solid shape of the tire is an almost ready-made container for water;

- a thick layer of rubber will reliably hold water;

- the tire is not afraid of temperature changes, so it will last for many years;

- A pool made of this material is easy to decorate. You can simply paint it in different colors, and it will be difficult to guess that this is an ordinary tractor tire.

The disadvantages of this material are:

- small size. This pool is not suitable for swimming or diving;

- due to the small diameter, which is slightly more than one and a half meters, more than two people cannot fit inside;

Carrying out material calculations for a tire structure

To create a pool from a tire, you need to choose a large model.

If you need a fairly large place for swimming, then the best option for this would be a tire from a Belaz truck.

The wheel diameter of this car ranges from 1620 to 3575 mm, and the tire width ranges from 498 to 1140 mm. The following table will help you choose the appropriate tire size.

To calculate the volume of the pool, you need to remember the school curriculum for the geometry course. To make these calculations, you need to use the appropriate formula: V=π·r 2 ·h, where V is the volume of a cylindrical pool; π – constant mathematical value equal to 3.14; r - radius of the circle (base of the figure); h is the height (in our case, width) of the tire. According to this formula, you need to know the radius of the circle. To do this, you need to divide the diameter value in half: 3.575:2 = 1.7875 mm.

We substitute the values, as a result of which we get the volume of the structure in cubic meters: 3.14 1.7875 2 1.140 = 11.4371 m 3, rounded to 11.438 m 3.

For the foundation of the future pool you will need sand and concrete. It is known that the sand cushion and concrete base will each have a thickness of 15 cm. This data is enough to calculate the volume of materials.

We make the calculation for sand: 3.14 3.1951 0.15 = 1.504 m 3. You will need a little more concrete mixture, since you need to add two more buckets for the bottom of the pool.

The finishing material is selected individually, taking into account the design decision for the design of the bathing area.

Required Tools

To install a tire pool, you will need the following tools:

- A sharp, strong knife.

- Shovel and bayonet.

- Containers for sand, concrete mixture and water.

- Concrete mixer.

- Building level.

- Yardstick.

Step-by-step instruction

The construction of a pool from a large tire is carried out in the following order:

- Using a sharp, strong knife, you need to make a cut on one side. To get a smooth edge, you need to cut along the intended tread circles. You should not use a grinder for these actions, since when cutting, some of the material will turn into small crumbs that will stick to the tool.

- Then you need to choose a flat piece of land and clear it. Fill in a layer of sand that needs to be compacted. In order for the sand to hold its shape and compress better, it needs to be moistened. The result should be a uniform layer 15 cm thick. Please note that the area with the sand cushion should be slightly larger than the diameter of the tire.

- You need to pour a concrete mixture on top of the compacted surface to create a layer of 15 cm. Place a tire on it. Pour two buckets of concrete inside it.

- All that remains is to decorate the pool and wait for the concrete to harden. To do this you need to wait about a week.

- The side surface of the tire can be painted with different paints. If you show your imagination, you can hide the tread relief with decorative stones or plants.

- After carrying out the above work, you can take water procedures.

DIY pool made from wooden pallets

Wooden pallets can be used as improvised material for making a pool. Due to their size and shape, they are convenient for building pool walls. The greater the number of pallets, the rounder the structure will be. Their optimal number is 9 pieces. In this case, a frame is made that will comfortably accommodate from 1 to 6 people.

A bathing area made from pallets has a number of advantages:

- the height of the sides of the pool allows it to be filled with a large volume of water;

- it is convenient to install a ladder and a slide;

- there is no need to dig a deep pit for the structure;

- if necessary, it is easy to dismantle and move;

- wood is an environmentally friendly material;

- Replacing any section is not difficult, you just need to drain the water.

The disadvantages of using pallets for building a swimming pool include the following:

- a wooden structure requires mandatory reinforcement, which is used as a textile tightening belt or stops;

- the structure must be covered with finishing material;

- wood must be treated with antifungal impregnations;

Every time, before pouring water, it is necessary to tighten the belts and check the integrity of the structure.

Construction calculations

To calculate the volume of a pool made from wooden pallets, you need to use the computational method of “truncating a square” and the formula: S=A 2 -a 2, where “A” is the side of the square into which the octagonal figure is inscribed, and “a” is side of the octagon. It follows from this that “a” will become the length of the side of the pallet, which is 1.2 m.

First you need to find the value of the capital letter “A” using the formula:

The value from the root is 1.41421356. Now, using this formula, we find the next value of the fraction, the result of which is the number 0.8485281. Then you need to substitute the results obtained into the formula to find the value “A” (the side of the square in which the octagon is inscribed): 1.2+2∙0.8485281=2.8970562 m.

Now you have all the necessary values to calculate the volume of an octagonal pool. Another formula will help with this: V=S base ·h, where “h” is the height of the pool, equal to 0.9 m. As a result: V=6.95·0.9=6.255 m3

Required Tools

To build a pool from wooden pallets, you need the following tools:

- Shovel and bayonet shovels.

- Hammer.

- Screwdriver.

- Concrete mixing machine.

- Jigsaw.

- Sanding machine or sandpaper.

- Yardstick.

- Cord and stakes.

- Large square.

- Construction level and plumb line.

- Pencil.

- Pliers.

- Plane.

- Self-tapping screws and nails.

Step-by-step construction of a swimming pool from wooden pallets

To erect a pool structure from wooden pallets, the following construction work must be carried out:

- Since the main material for construction is wood, it must be treated with special antifungal impregnations.

- Wooden pallets measuring 120x90 cm were used as sections to create the octagonal structure.

- Then, you need to dig a round hole with a diameter slightly wider than the future pool.

- Level the bottom of the pit and fill it with gravel to create a uniform layer of at least 20 cm.

- Inside the pit, assemble a frame of eight pallets. They must be mounted with a continuous surface inside the structure. Connect wooden elements using boards that should be attached along the side of the pool. Reinforce the joints of the structure with wooden blocks using self-tapping screws.

- Cut holes in the frame to install the drainage system.

- When the structure is assembled, it must be additionally secured with two tightening straps.

- Install pipes for supplying and draining water into the prepared holes.

- It is necessary to drive wooden wedges into the space between the sections of pallets and the wall of the pit. This will further strengthen the frame.

- Fill the bottom of the pool with a 10 cm layer of concrete mixture, which will harden in 5–7 days.

- When the pool is ready, start covering it with waterproofing material. As such, use PVC film.

- Attach OSB boards to the front side of the frame. They will hide unsightly areas and connecting elements of the frame.

- Decorate the pool to your liking. The fastest and most beautiful way is to cover the sides with rolls of reeds.

How to make a swimming pool using plastic bottles

Even plastic bottles are used to build a homemade pool. This polyethylene product has established itself as a practical and convenient building material. Layed on cement in several rows and filled with sand, they form a fairly strong wall.

Building a pool from this available material has its advantages, expressed in the following:

- plastic bottles are widely used in everyday life, so purchasing them is not difficult;

- the material is low cost;

- plastic is not susceptible to moisture, therefore it is a waterproofing material;

- a pool using plastic will last a very long time;

- the material allows you to build a pool of any shape.

The disadvantage of this material is the following:

- During laying, a large amount of sand is needed to fill each bottle, and concrete mixture for vertical and horizontal joints.

Material calculation

Polyethylene bottles are a convenient building material. They can be used to build structures of various shapes and heights. To determine how many bottles are needed to build a pool with parameters of 4000x2000x1500 mm, you need to know the parameters of one bottle. This material is made in various sizes, but a regular 1.5 liter bottle measures 345x85 mm.

Since the bottles will be laid on their sides so that the neck is directed inward, it is necessary to divide the total length of the future pool by the width of the bottle: 4000:85 = 47 pieces, necessary for one row. Now you need to calculate how many bottles are needed for the width: 2000:85 = 23.5 pcs. Next, you need to double the obtained values, the pool will be rectangular in shape: (47 + 23.5) 2 = 141 bottles. This is the amount of material needed for the perimeter of the first row.

The height of the pool is 1500 mm, so you can calculate the number of rows: 1500:85=17.6. A total of 17.6 rows of bottles are needed to build the sides of the swimming area. Now you need to calculate how much material is needed to build the entire pool. To do this, multiply the number of bottles in the first stack by the total value of the rows: 141·17.6 = 2481.6 - round up to 245 bottles.

This method of building a pool involves filling each bottle with sand. Therefore, it will not be difficult to calculate the total volume of sand required to fill a one and a half liter container. You need to multiply the total number of bottles by one and a half: 2481.6·1.5=3722 kg of sand.

In addition, sand is needed to create a 15 cm thick layer under the concrete base. We calculate the total volume of bulk material. To do this, you need to multiply the width, length and height of the sand cushion: 4 2 0.15 = 1.2 m 3 or 120 kg. Now you need to add up all the indicators for sand: 3722 + 120 = 3842 kg of sand.

The concrete base will have a thickness of 15 cm and will repeat the parameters of compacted sand. Therefore, its total volume is 120 kg.

List of tools

To create a pool from scrap materials you will need the following tools:

- Scoop and bayonet shovels (for a large pool - a mini-excavator).

- Screwdriver.

- Concrete mixing machine.

- Containers for garbage, water and concrete mixture.

- Yardstick.

- Cord and stakes.

- Large square.

- Construction level and plumb line.

- Pencil.

- Self-tapping screws and nails.

Step-by-step instructions for construction

The design of a pool made of plastic bottles involves the following construction steps:

- First of all, you need to choose a flat piece of land and clear it. It is best to install a slab foundation for this pool.

- Dig a pit measuring 400x200 cm, 15 cm deep.

- Level and compact the bottom of the hole. Pour wet sand on top, distribute it evenly over the entire surface and compress until a layer of 15 cm is obtained. Additionally, the bottom can be covered with a layer of gravel.

- Make formwork for pouring concrete from wooden boards 20–25 cm wide. To prevent the wooden frame from falling apart under the pressure of the mixture, wedges must be driven into the ground on its outer side.

- From reinforcing bars with a diameter of 8 mm, make a lattice that will strengthen the concrete base. Secure the intersections of the reinforcement with wire. The grid cells should have a size of 10x10 cm and an area of 8 m2.

- This metal frame must be laid on the bottom so that it does not touch the sand. To do this, in a checkerboard pattern you need to install a small hill of halves of bricks.

- Install a reinforcement cage on top.

- Do not forget about connecting pipes and other communications.

- Pour the concrete, leveling it with a rule or a long, flat board.

- Leave the base for the concrete to harden. The mixture will harden in about 6-8 days.

- Now you can move on to building the walls of the pool from plastic bottles.

- First you need to mark the shape of the future pool.

- Fill each plastic container with sand and close with a lid.

- Apply a strip of cement equal in width to the length of the bottle.

- Make a frame from metal rods with a diameter of 0.3 mm. It is necessary as a connecting link between rows of bottles. The length and width of the frame must correspond to the dimensions of the wall strip.

- Place bottles filled with sand on the cement, close to each other. Fill the gaps between them with the mixture. When the first row of bottles is laid, they need to be filled with cement on top and a metal frame laid.

- Remove the formwork from the boards.

- Similarly, lay PET bottles to the desired height.

- Wait until the concrete hardens.

- When the walls are ready, they need to be plastered.

- To create a reliable waterproofing layer, the inner surface of the pool can be covered with bitumen.

- When everything is ready, you can begin finishing work. To do this, you need a PVC film, which is designed to cover the inside of the pool. Excess fragments of the film must be cut off, and the joints must be welded and treated with sealant.

- Decorate the area around the pool.

Swimming pools in the country have long ceased to be a rarity. Only the sizes of such structures and their shape vary. It can be either full-fledged, fully equipped with appropriate equipment, or small, intended only for bathing children.

Types of country pools and their features

First you need to decide which of the country pools you plan to place on your site. According to installation methods, they are divided into:

Based on the materials used to make them, garden pools are divided into products made from:

It is better to protect a stationary pool with at least a simple canopy. In this case, less debris and fallen leaves will accumulate in it.

Filtration system

Without a high-quality filtration system, stationary garden pools will simply become overgrown with mud in a very short time. Depending on the method of water circulation in them, you can choose any of the cleaning systems:

Monolithic concrete pool for a summer residence

From durable reinforced concrete you can make both a small swimming pond and a full-fledged swimming pool equipped with modern equipment. But in both cases, the process of its arrangement is largely similar. We will describe in detail how to build a swimming pool at your dacha with your own hands from concrete.

Selecting a location and preparing the area

To ensure that the water in the pool warms up as quickly as possible, it is placed in an open space, away from tall buildings and trees that block the sun. Close proximity of vegetation is also undesirable because in the fall, falling leaves will clog the pool, and it will take much more time to clean it. The growing roots of such powerful plants as poplar, willow or birch can easily destroy even concrete.

To ensure that the water in the pool warms up as quickly as possible, it is placed in an open space, away from tall buildings and trees that block the sun. Close proximity of vegetation is also undesirable because in the fall, falling leaves will clog the pool, and it will take much more time to clean it. The growing roots of such powerful plants as poplar, willow or birch can easily destroy even concrete.

It’s not at all difficult to build a small pool at your dacha from scrap materials to enjoy swimming in refreshing water all summer. You can easily make this design yourself.

What materials can mini-pools be made from?

With the onset of summer heat, many owners of suburban areas and summer cottages begin to dream of their own artificial pond in the garden. You can purchase and entrust its installation to specialists or equip a full-fledged swimming pool with a pavilion and a heating system for year-round use. But the cost of such structures is not affordable for everyone.

Fiberglass pool

Because of this banal reason (lack of financial resources), many refuse to build swimming pools. And more resourceful home craftsmen find an elegant solution to this problem. They show their imagination and build summer mini-fonts for their dacha with their own hands, spending a minimum of money and time on this operation. You can make a small pool in the garden from:

- tires;

- old bath;

- plastic bottles;

- concrete ring;

- metal container;

- wooden blocks and boards;

- gabions.

These materials make excellent mini-pools for summer cottages. Let's figure out how you can make open-air fonts with your own hands using the indicated available materials.

A tire pool is a popular option among summer residents.

You can make a tire structure without the slightest difficulty if you can find a tire that fits the size. It is best to use rubber from a combine or tractor. These tires are ideal in size for constructing mini-pools for summer cottages, as they have a diameter that is sufficient for comfortable swimming for an adult. The algorithm for constructing a hot tub from a large tire is as follows: cut out one side of the tire (be sure to leave the side) using a hacksaw and a well-sharpened knife. This operation is quite labor-intensive and requires some care.

Small tire pool

Some craftsmen try to make the process of cutting a tire easier and use a grinder. It is better not to resort to this method. The grinder breaks the tire, the latter begins to disintegrate into small pieces and stick to the hands, as well as to the working tool. You will get an extra headache. Select a flat piece of land in the garden where the homemade hot tub will be installed. Clean the chosen one (it should be slightly larger in size than the cross-section of the tire), fill it with construction sand, making a so-called pillow. Fill the sand layer with cement in a circle. The thickness of the cement fill is taken to be about 15 cm. Place the prepared tire on the cement mortar. Level the cement fill and, if necessary, add another 2-3 buckets of mortar.

The mini-pool can be made more attractive. Craftsmen advise covering its cement sides with brick or natural stone, laying them out with colorful mosaics, or simply painting them. Such work is done with your own hands and does not require any special knowledge. You can use a tire pool no earlier than 7–8 days after it has been filled. This is exactly how long it takes for the cement to completely harden.

A font in the garden from an old bathtub is much simpler

Thrifty owners never throw away old things. Many people these days install new acrylic bathtubs in city apartments, and transport old steel or cast iron structures to the countryside, hoping that they will still be useful. And indeed it is. They will be useful for building a mini-pool with your own hands. How to make a font from an old bathtub? Elementary. First, choose a place to install the pool. Experts advise choosing a site located in the shade of trees. Then the metal bath will not heat up.

Small pool from an old bathtub

After this, dig a small pit at the selected site. Its dimensions should be such that the bathtub can easily fit into the pit at 3/4 of its height. Cover the bottom of the pit with a 20-centimeter layer of sand. Then carefully lower the bath into the prepared hole. In this case, you need to ensure that the edges of the metal structure are horizontal. Pour sand into the gaps between the bathtub and the walls of the pit, compact it thoroughly, add building material, compact it again. You dig a small trench around the perimeter of the installed pool, fill it with stones, creating unique edges.

The area around the font can be made more beautiful by using decorative concrete painted in different colors.

Using the described method, it is better to make a swimming pool for a summer house from a cast iron bathtub. But it is also allowed to use a steel font. But in this case, it will have to be restored by restoring the damaged enamel coating. This procedure is done with your own hands using liquid rubber, which is used to treat the internal areas of the bathtub with enamel defects. If you want to decorate your homemade pool, treat it from the inside with tile adhesive, and then place pebbles of different sizes on the adhesive (there are plenty of them on any river bank). The effect will be amazing.

Pools made of gabions and a concrete ring - we make them for centuries

If you want to build a stronger and more reliable pool with your own hands, pay attention to the following two options, which are implemented from such available materials as gabions and a ring of concrete. They are easy to work with. Gabions are metal (steel) frames into which ordinary stones are placed. The shape of such structures can be different. You need to purchase a durable film, a base mesh and mix the concrete.

Gabion pools

And then do the following:

- On the site under the pool, pour a concrete base. Its geometric parameters are taken to be slightly larger than the size of the future font.

- Lay a steel mesh on the concrete and place stones on it (in separate layers).

- Attach the film to the inside of the pool. It is necessary to protect the structure from moisture.

- Fix the film (as securely as possible) on the upper edge of the gabion.

That's all. Your mini-pool is ready. It will delight you with its high strength, long service life and quite decent appearance. You can also quickly and easily make a font at your dacha from a ready-made concrete ring. Choose the diameter of such a product yourself. Rings with a cross section of 1–2.5 m are available for sale. Buy the one that suits you. To build a bowl from a ring for summer swimming, you will need construction sand, concrete mortar and geotextiles. The work is carried out as follows: dig a pit, focusing on the dimensions of the ring used, make a cushion of sand, lay geotextile material on it, and concrete the bottom.

After this, lower the concrete product onto the prepared base. Fill all the gaps with sand and compact it. It is advisable to additionally decorate the completed pool in some unusual style. You are allowed not to concrete the bottom of the future ring pool with your own hands. Instead of this rather labor-intensive operation, you can place a finished concrete cover under the ring. Such products are used for arranging inspection wells. The main thing is not to forget to seal the hole that is present on such covers.

Wood is a suitable material for construction

Many people do not believe that it is quite possible to build a font in the garden from 5x5 cm wooden blocks, 2.5 cm thick boards and 2x2 cm slats. But such structures are characterized by increased reliability, real durability and high strength.

Wooden font in the garden

Of course, if all the work is done correctly. A wooden pool is built according to the following scheme:

- Apply wood varnish to the bars, boards and slats, and then cover them with a layer of enamel.

- You make shields from wooden elements. Their dimensions should be thought out in advance by creating a drawing of the future mini-pool.

- You assemble the panels into a single structure (make a frame from bars and cover it with panel blanks). At this stage, it is important to achieve a very tight fit of the individual elements of the future wooden pool to each other.

- You dig a hole. Its depth depends on the height of the panel structure, which should plunge 2/3 into the pit.

- Place a layer of gravel at the bottom of the hole.

- Install a structure made of panels into the pit (pre-cut holes in it necessary for installing pipes through which water will be supplied and drained).

- Installing pipe products.

- Insert 20x20 cm metal plates and 20 cm long wood wedges into the gaps between the pit and the shields (they should be connected to each other). Drive in the wedges connected to the plates and fill the pit with gravel.

- Fill the bottom with the installed panel structure with a layer of about 10 cm of cement. As soon as it sets, lay a waterproofing material on it - polyvinyl chloride film.

The font is ready. Ennoble it and use it for your health.

Artificial ponds made from bottles and metal containers

Plastic containers from a variety of drinks can also be used to build a pool in the garden. You need to think over the shape of the future artificial reservoir and prepare a site for it (remove the top layer of soil, add a cushion of sand, and put a layer of gravel on top). After this, the base of the pool is filled with concrete mixture, and you can begin laying the structure. In this case, plastic bottles are embedded in the bottom and wall surfaces of a homemade font.

Pool from an old tank

During laying, both horizontal and vertical joints should be filled with concrete. Then the structure will be truly airtight. It’s even easier to make a pool from a suitable container - waste, construction, shipping, or used for shipping. True, in this case you need to be able to use a welding unit. The work is performed as follows:

- Inspect the container for its integrity. Weld all the cracks found.

- Carefully treat the metal container with a composition with anti-corrosion properties.

- Bury the container prepared in the above manner into the soil to the depth you need.

- Tile or paint the sides of the pool.

With the right approach to its construction, your homemade pond will become the highlight and pride of your summer cottage!

To date, several types of swimming pools have been developed, most of which can be installed on your own. The best option is a full-fledged monolithic concrete pool. This design is characterized by the highest reliability and durability.

Read the instructions provided and get started.

Set for work

- Level.

- Roulette.

- Stones.

- Rope.

- Steel knitting wire.

- Reinforcing mesh.

- Small pegs.

- Fittings.

- Shut-off valve.

- Wooden boards or shields.

- Anti-corrosion agent for metal processing.

- Self-tapping screws.

- Cement.

- Sifted sand.

- Material for waterproofing.

- A block for compacting backfill layers.

- Shovels.

Preparatory activities

Decide on the desired shape and required dimensions of the artificial reservoir to be equipped.

When determining the optimal size of the pool, consider how many people will swim in the pond. For a large family, it is better to immediately equip a spacious container.

In accordance with practical experience, the optimal depth of the reservoir is 1.5-1.8 m; in width and length, 4 m is most often sufficient.

For the rest, be guided by your needs and requirements. For example, if you plan to use the pool for full-fledged training, consider this point when determining the required length and width of the reservoir.

Choose a convenient location to build a swimming pool.

The main thing is that the space is not covered by trees. Because of the trees, the water in the pool will not be able to warm up properly and, in addition to this, will be constantly polluted by fallen leaves.

Also, low-lying areas are not suitable for arranging swimming pools, because... with such an arrangement, the water will be constantly polluted by rain flows.

Marking and digging a pit

Armed with a tape measure, stakes and cord, start marking the construction site.

The dimensions of the construction site should be 0.5 m larger than the dimensions of the future pool on each side. To mark boundaries, drive pegs into the ground and stretch a cord between them.

Completely remove the top fertile ball of soil.

Dig a pit of the required dimensions, and the bottom of the hole should be approximately 25-30 cm below the desired depth of the pool.

Carefully level the walls of the pit. The bottom of the pit must be given a slight slope.

Construction of a monolithic pool

Proceed directly to the construction of a monolithic pool.

Place a 20-30 cm layer of sand on the bottom of the pit. Carefully compact the laid material and cover it with waterproofing.

The modern market offers a fairly large range of effective ones. To ensure high-quality moisture protection, roofing material is well suited. This is a practical, reliable and inexpensive material.

Lay roofing felt. You can use molten bitumen to attach the material.

Lay the waterproofed surface with stones. Lay a ready-made reinforcing mesh on top of the layer of stones, or make it yourself from metal rods.

Create a drainage hole. Its depth should be slightly greater than the depth of the main reservoir. Install a pipe into the hole to drain water. The end of this pipe must be inserted into the reservoir. Equip the pipe with a shut-off valve to drain the water.

Fill the drainage hole with a fairly thick layer of gravel. Install an overflow and skimmer system to purify the pool water.

Place reinforcing bars around the perimeter of the pit in 30 cm increments. Maintain a 50 mm gap between the reinforcement and the edges of the reservoir. Fasten the reinforcement bars with wire.

Fold from boards. Maintain a 15-centimeter gap between the formwork and the walls of the pit.

At the same stage, consider installing pipes and equipment for pumping and supplying water. Or you can use external systems of pumps and hoses - whichever is more convenient for you.

Start concreting the pool. You can order or make it yourself.

Pour the concrete gradually and slowly, in a horizontal layer.

Also fill the voids between the formwork panels and the pit walls. Give the mixture a month to gain strength and begin arranging the pool.

Do the interior design at your own discretion. You can tile the bowl. Or you can line the bottom with a 10-centimeter layer of clean sand, and then the pool will look like a body of natural origin.

Other private pool options

Frame systems

Such structures are constructed from wood with finishing cladding of tin or aluminum. Aluminum sheets have an attractive appearance and are superior to tin in terms of reliability and service life.

The frame straps are made from pine timber. Intermediate parts can be made from any thick, high-quality boards. To provide additional rigidity to the structure, braces made of strong boards are used.

Among the main advantages of frame pools, it should be noted that there is no need to carry out large volumes of excavation work and the possibility of dismantling the structure during the cold season.

Changing the water in such a pool is carried out using a flexible garden hose, which can be conveniently fixed at the bottom of the tank. Waste water from the pool can be used to water the garden.

All joints of the frame structure are subject to mandatory sealing. To give the structure the required tightness, even ordinary polyethylene film is well suited.

Wooden elements must be treated with an antiseptic.

The installation of frame pools usually costs less money compared to the cost of erecting a monolithic structure, while such reservoirs have a fairly solid appearance and fit well into the design of the site.

Find out how to build with step-by-step instructions in our new article.

To arrange a pool, if desired, you can even use ordinary polyvinyl chloride film. This material has a rather attractive appearance and acceptable performance characteristics.

The film tolerates contact with water normally, ensures proper tightness of the structure and allows you to save on waterproofing the reservoir.

Even if cracks appear in the container, a properly installed polyvinyl chloride film will retain water.

PVC film can be used both when arranging a new reservoir and when repairing an old pool. Moreover, to build such a structure, there is no need to carry out extensive excavation work: the elements of the film are simply fastened together using the temperature welding method, resulting in a very durable bowl.

The pool is installed on a pre-prepared base and fixed with a frame made of boards.

Today, swimming pools with a base made of fiberglass are very popular. This durable material can withstand even the most severe mechanical loads and does not require any additional coating.

Among the disadvantages of the design under consideration, one can only highlight the need for mandatory connection of all communications.

The bowl is installed on a solid concrete base.

Thus, there are many pool options available for the owner to choose from. Having studied the features of each type of artificial reservoir considered, you can come to the optimal solution and build the pool of your dreams without outside help.

Good luck!

Prices for prefabricated and inflatable pools from the manufacturer Azuro

Prefabricated and inflatable pools Azuro

Video - How to build a swimming pool with your own hands